Vacuum Casting Capabilities

Vacuum Casting

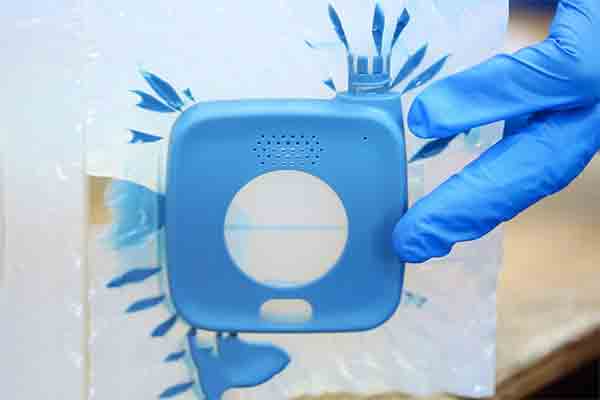

Polyurethane vacuum casting is a method for making high quality prototypes or low volumes of parts formed from inexpensive silicone molds. Copies made in this way show great surface detail and fidelity to the original pattern.

Materials

Hundreds of casting polymers are commercially available to reproduce any conceivable hardness and surface texture. It is also possible to make parts that are fully opaque, translucent or completely transparent depending on your application. See more information on available materials.

Tolerances

The finished dimensions of vacuum cast parts are dependent on the accuracy of the master pattern, the part’s geometry and the type of casting material used. Generally a shrinkage rate of 0.15% is to be expected.

Vacuum Casting Specifications

| Basic Info | Details |

|---|---|

| Min Part Size | 5mm (L) x 5mm (W) x 1mm (H) |

| Max Part Size | 750mm (L) x 500mm (W) x 350 mm (H) |

| Max Part Weight | Net weight 1.8KG |

| Tolerances | +/- 0.3% (with a minimum of +/- 0.3mm on dimensions smaller than 100mm) |

Vacuum Casting Machines

| # | Brand | Max Part Size (mm) |

|---|---|---|

| 2 | TOP50 Vacuum Machine | 400 x 400 x 400 |

| 1 | TOP80 Vacuum Machine | 750 x 500 x 350 |

Can’t find what you’re looking for?

Get in contact and we can help find a solution for your next project.