Mold Tool Materials

We make plastic injection molding tools and dies from S136H, 2316H, H13, 2316H, P20, 8407 (hardened) and NAK80 (hardened). Additionally, we offer standard SPI finishes, EDM texturing and a range of etched textures. Read more about our rapid tooling service.

Each of these material types will have distinct advantages for certain applications. Considerations include:

- Cost of the raw material

- Durability and resistance to corrosion or abrasion

- Machinability

- Ability to take a high surface polish

- Time required for heat treatment

- Expected tool life

Contact our technical specialists to learn more about which one is right for you.

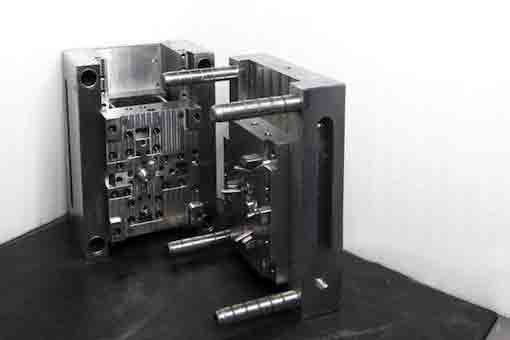

Tool For Injection Molding

Injection Molding Production Parts

Plastic Injected Part Materials

There are thousands of thermoforming and thermosetting plastics to choose from for your project. In addition, mechanical and chemical characteristics can also be enhanced with additives like glass fibers, UV stabilizers and lubricants. Our materials sheet will give you more detailed information about the standard types and the tolerances to expect with each.

Your choice of resins may depend upon one or more of the following considerations:

- UV, chemical, abrasion and impact resistance

- Cost of raw material

- Mechanical strength

- Weight and density

- Flexibility

- Transparency

- Recyclability

Contact one of our technical specialists to learn more about material properties.

Production Of Injection Molded Parts

Golden Samples For Plastic Resin Material Verification

Get Your Plastic Injection Project Started Today

Once you send us a 3D CAD file, our engineers will review draft angles, wall thickness, corner angles, material type and more to ensure it is optimized for manufacturing. We will also make sure correct materials are combined with the correct design considerations so your project meets and exceeds your expectations. Contact us today for your free quote.

Plastic Injection Molding Service