Additional Services

Michigan CNC Machining Parts, Inc. offers a variety of additional manufacturing services that help you to to bring your projects to completion. They include:

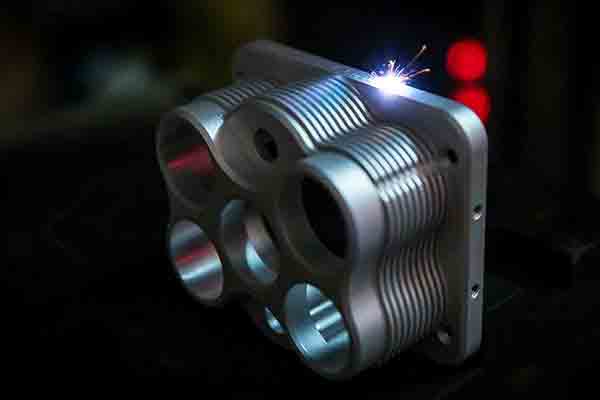

Laser Marking / Laser Etching

Ideal for making permanent markings on the surface of many types of metals and some plastics. Laser marking doesn’t alter part geometries or cause damage to the mechanical properties of the substrate.

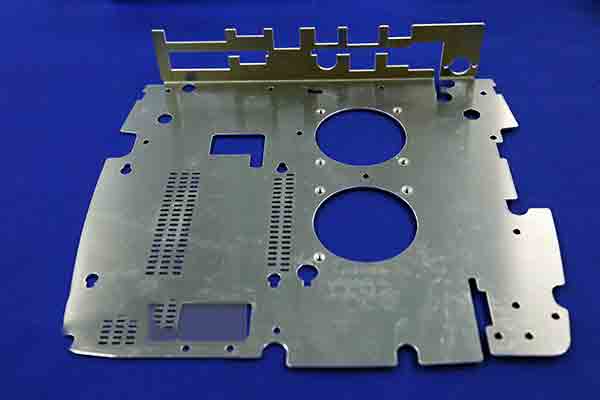

Sheet Metal Stamping / Bending / Drilling

Many products rely on the use of sheet metal to make enclosures, brackets, mounting plates and other fittings from steel and aluminum. We offer limited sub-contracted sheet metal fabrication services on select projects. Contact us for more details.

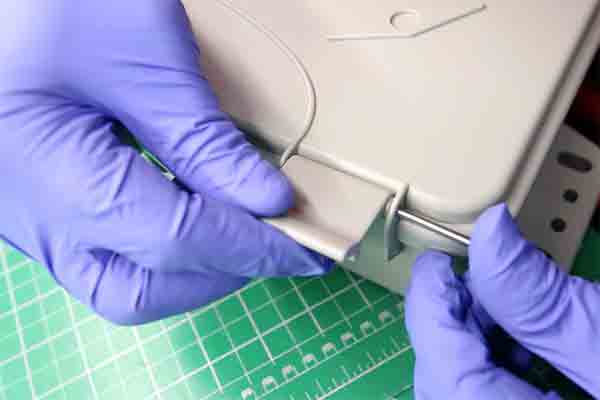

Light Assembly

We provide light mechanical assembly, both in-house and sub-contracted. Because of the range of possible applications, we advise you to speak with a sales account manager about your exact needs.

Welding / Soldering / Brazing

Metal joinery is accomplished by welding, soldering or brazing. We only outsource these services on select projects. Contact us for more details.

Custom Packaging

If you require custom packaging for your finished products, we can offer a list of printing and packaging options to choose from.

Get Your Project Started Today

We are always looking for more ways to meet your individual needs. Your regional sales representative is the best resource for learning more about what auxiliary services are available, so contact them today.

Further Reading

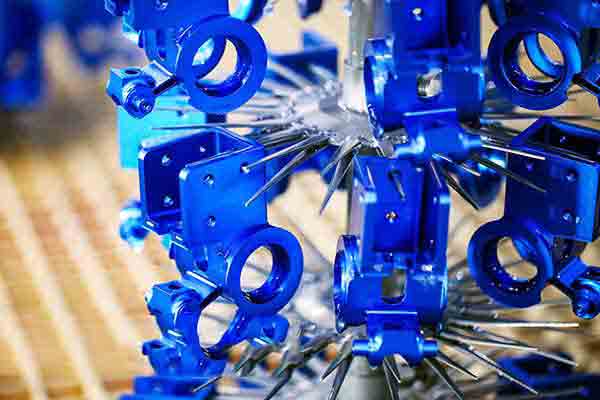

Anodized Aluminum Colors: Understanding Color Matching

There are many challenges when trying to match colors on anodized parts. Some of these challenges come from the process itself, and some are a result of the metal alloy being used.

Product developers need to know about the key factors that affect color consistency and color matching in Type II anodizing for aluminum. Read More…