Rapid Tooling

Request a QuoteRapid Toolmaking Service

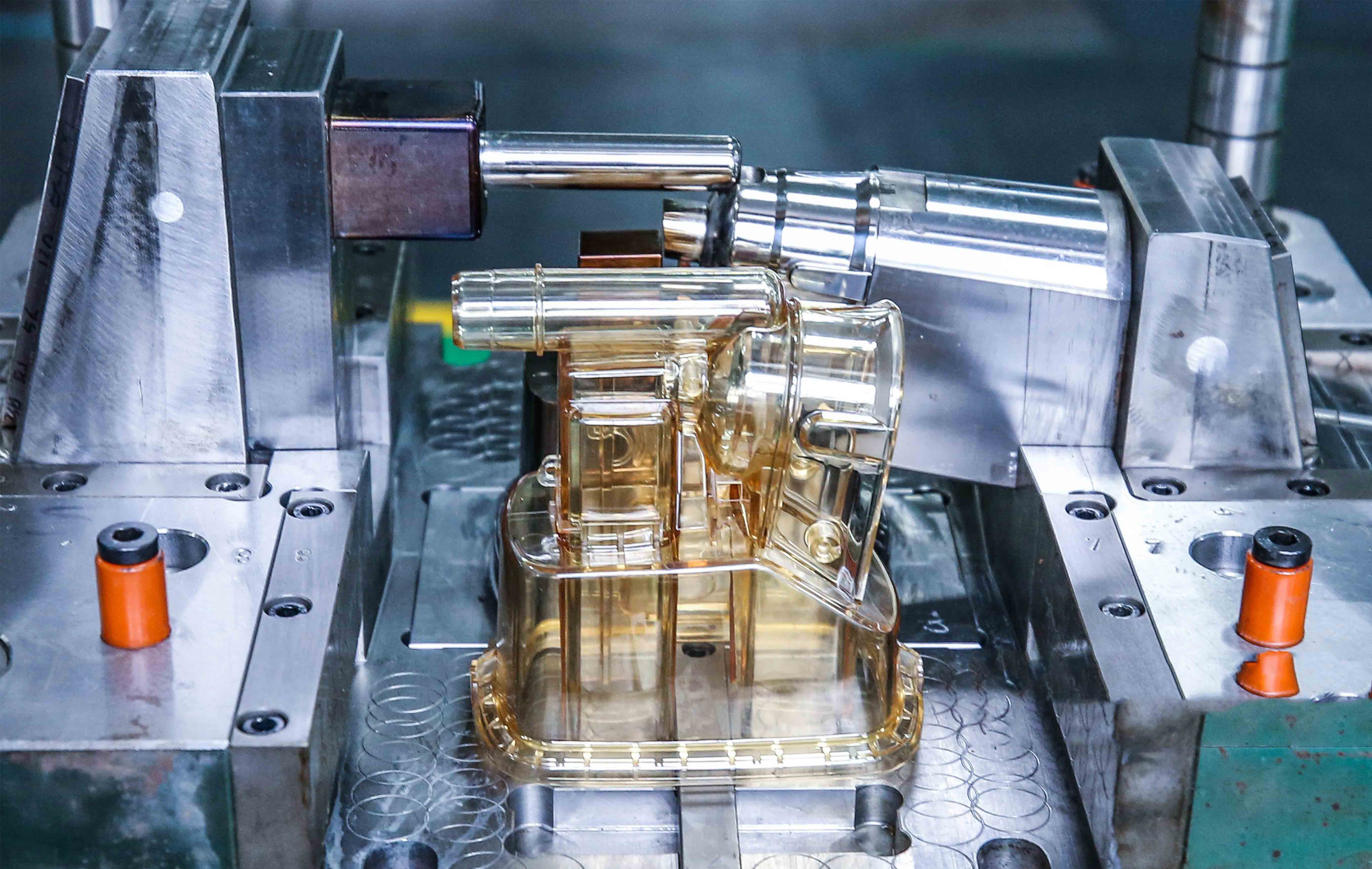

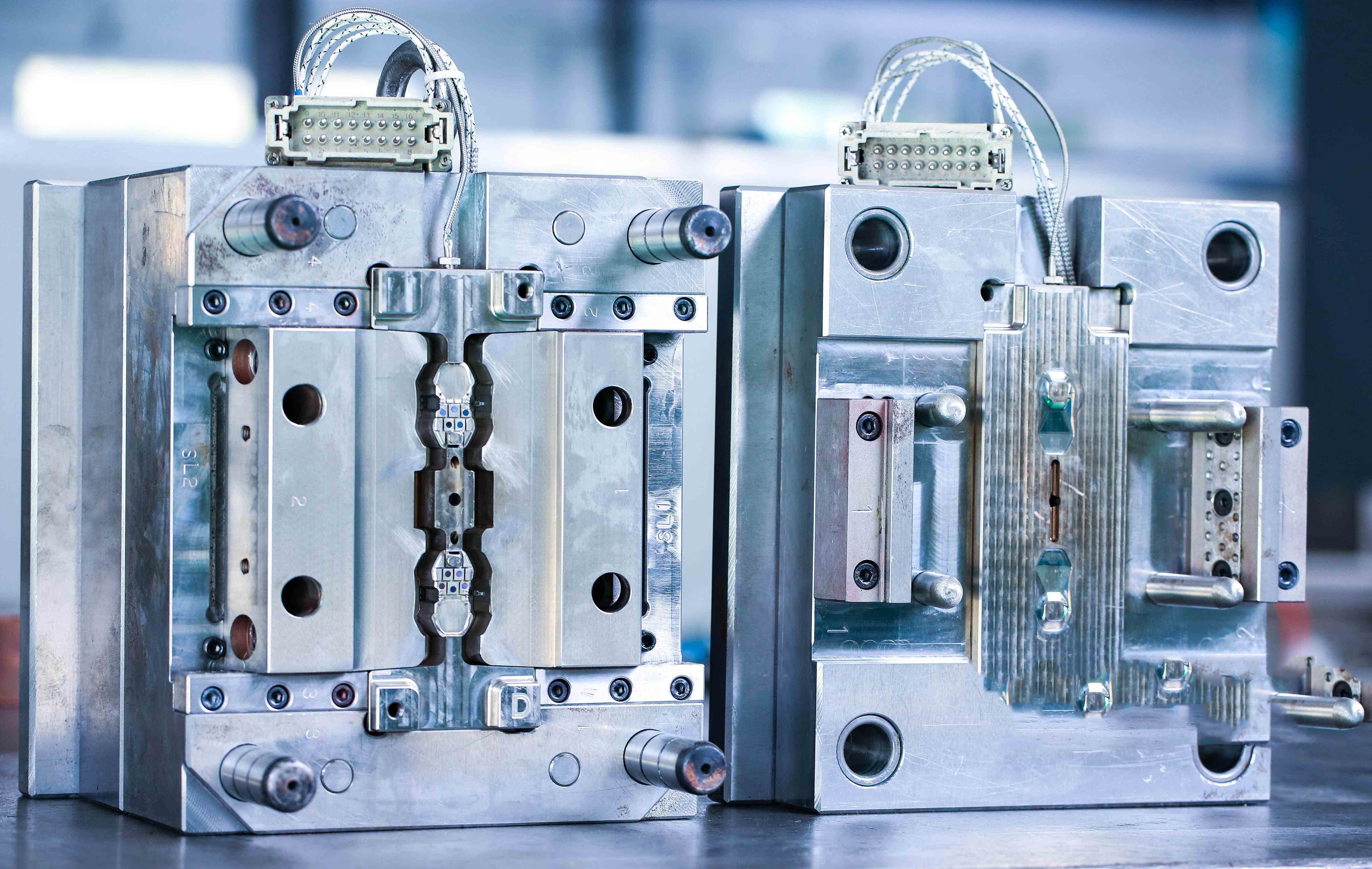

Michigan CNC Machining Parts, Inc. has the equipment, the skill and the experience to help you create world-class rapid tooling for plastic injection molding and pressure die casting.

Using your qualified CAD drawings in our proprietary OMOM system, a single master toolmaker will take charge of your project from start to finish to ensure the fastest possible turnaround times to support rapid prototypes, new product introduction and full production volumes up to hundreds of thousands of high-quality parts.

Toolmaking Process

Your rapid mold tools are made with high-quality P20, Nak80 or H13 tool steels. We use imported multi-axis CNC mills, grinders and EDM machines to create complex geometries with multiple surface finishes, from the highest optical polishes to matte and everything in between. We can even apply custom textures using MoldTech photoetching. Our partnership with Guhring of Germany ensures that only the finest cutting tools are used to maximize speed while holding tight tolerances in any material.

Advantages to Star’s Toolmaking Service

When you choose Michigan CNC Machining Parts, Inc. for quick turnaround mold tools, you get a host of services to support any project, including:

- Design for Manufacturing analysis

- Overmolding

- Multiple cavities

- Inserts

- Heated cores

- Manual and hydraulic sliders

And much more!

Material Verification

We use X-ray fluorescence and spectrophotometry to measure the precise molecular composition of all the raw materials we use for your tooling. You can be assured you get exactly the material grade you specify.

Our attention to detail doesn’t stop when your mold is completed. We’re not satisfied until your finished parts have been fully verified in our modern quality control metrology lab.

Toolmaking Tolerances and Finishing Guidelines

Unless otherwise specified by you, our standard tolerances conform to DIN-2768-1-fine.

Surface finishes for the core and cavity of mold tools can be made according to the classification system of the Plastics Industry Association using their general surface finishing guidelines. Additional finishes can be applied using proprietary MoldTech® or other third-party photoetching technologies. Please enquire for more information about these services.

If you need the finest in rapid toolmaking services, contact Michigan CNC Machining Parts, Inc. today.

Why Choose Michigan CNC Machining Parts, Inc.® for Rapid Tooling?

✓ Excellent Efficiency with Mass-Production Quality

Our team combines unparalleled experience with the industry’s leading equipment to maximize speed and quality for our rapid tooling services. To meet even the most demanding timetables, we deliver 15- to 25-day tools with mass-production quality.

✓ A Proven Proprietary OMOM System

Our proprietary One Man One Mold OMOM system allows a single master toolmaker to take charge of your project from start to finish. Simply give us your qualified CAD drawings, and we’ll handle the rest. Rapid tooling has never been this easy, or this fast.

✓ Intelligent Pricing for Every Project

We never require a minimum order volume or minimum dollar value, and we use state-of-the-art AI quotation algorithms to get our clients quotes in 24 hours or less in nearly all cases.

✓ Industry-Leading Equipment, Uncompromised Testing

Our projects start with extensive material testing to ensure performance involving both x-ray fluorescence and spectrophotometry to confirm the integrity and composition of all the materials we use. From there, we utilize industry-leading equipment like multi-axis CNC mills, grinders, EDM machines and more to ensure that our rapid tooling services are completed on-time to your 100% satisfaction.

✓ Design for Manufacturing Support

Our goal is to make your product the best it can be. To that end, we proudly offer design for manufacturing (DFM) support with every quote, if needed. If you are unable to visit our facilities in person, we offer detailed video files showing all production steps, plus video conferencing and general support.

Michigan CNC Machining Parts, Inc. Rapid Tooling Service FAQ

What makes Michigan CNC Machining Parts, Inc.’s rapid tooling service unique?

Separating our team from competing manufacturers are years of tooling expertise combined with the industry’s latest equipment. This combination enables our staff to create world-class rapid tooling for pressure die casting and plastic injection molding.

We also offer a number of additional services to complement our rapid tooling service, including: design-for-manufacturing analysis, overmolding, multiple cavities, inserts, heated cores, manual and hydraulic sliders, finishing and more.

Can Michigan CNC Machining Parts, Inc. provide design services, industrial design support or product development support as an extension of its rapid tooling services?

Yes. Design and product development is integral to our rapid tooling services. Now available for all incoming RFQs, we provide a detailed design-for-manufacturing review of all CAD designs we receive. We also offer light assembly services to meet your needs.

What are Michigan CNC Machining Parts, Inc.’s quality standards for its rapid tooling services?

Our rapid tooling service reduces tooling time without reducing quality. We do this with rigorous material verification along with a streamlined manufacturing process that uses a single master machinist who makes your tools from start to finish. Rapid tooling is ideal for prototyping, new product introduction and as bridge tooling in low to medium volumes.

How do I get a quote for Michigan CNC Machining Parts, Inc.’s rapid tooling services?

We make it easy to get a fast quotation. Simply upload your CAD files and product details and we’ll send you a free quotation within 24 hrs. or less.

Get In Touch Today

Request Your Free Rapid Tooling Quote Today

Our improved algorithm decreases rapid tooling quotation times by up to 90%. Most quotes are delivered within 24 hrs. and usually much less, depending on project details.

Your customer support partner will contact you directly to ensure you’ve received and understand all aspects of your quotation and to answer any questions you may have.

Request a Quote