Aluminum Extrusion Service

Request a QuoteWhy Choose Michigan CNC Machining Parts, Inc.® for Aluminum Extrusion?

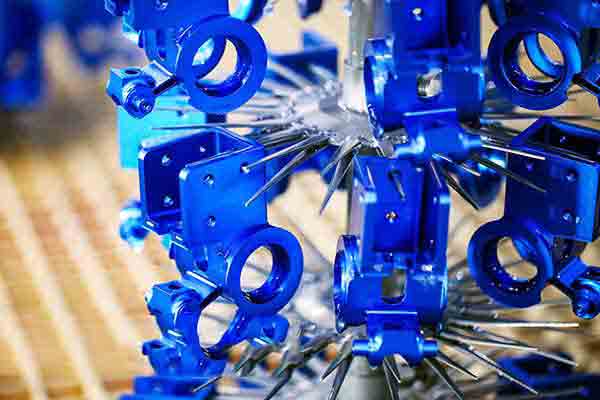

Used in industries ranging from construction to consumer electronics, aluminum extrusion is a manufacturing process in which aluminum alloy is pushed through a die with a specific cross-sectional profile. Both fast and straightforward, aluminum extrusion yields products that are lightweight, strong and resistant to corrosion. Here are several reasons to choose Michigan CNC Machining Parts, Inc. for aluminum extrusion services.

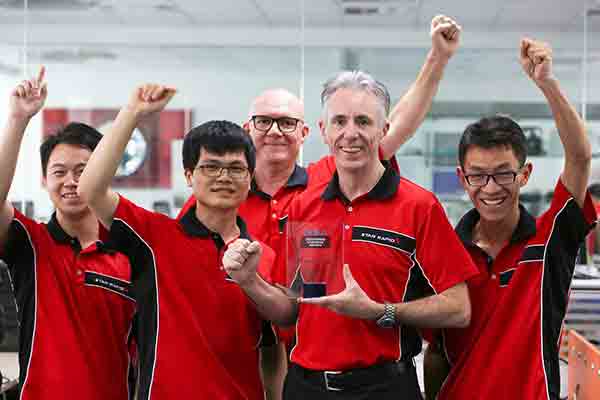

An Experienced Team

We have experienced engineers and project managers on-site to oversee your project, while an international sales team is at your service and in your region to facilitate fast and clear communication every step of the way.

Services to Complete a Wide Range of Projects

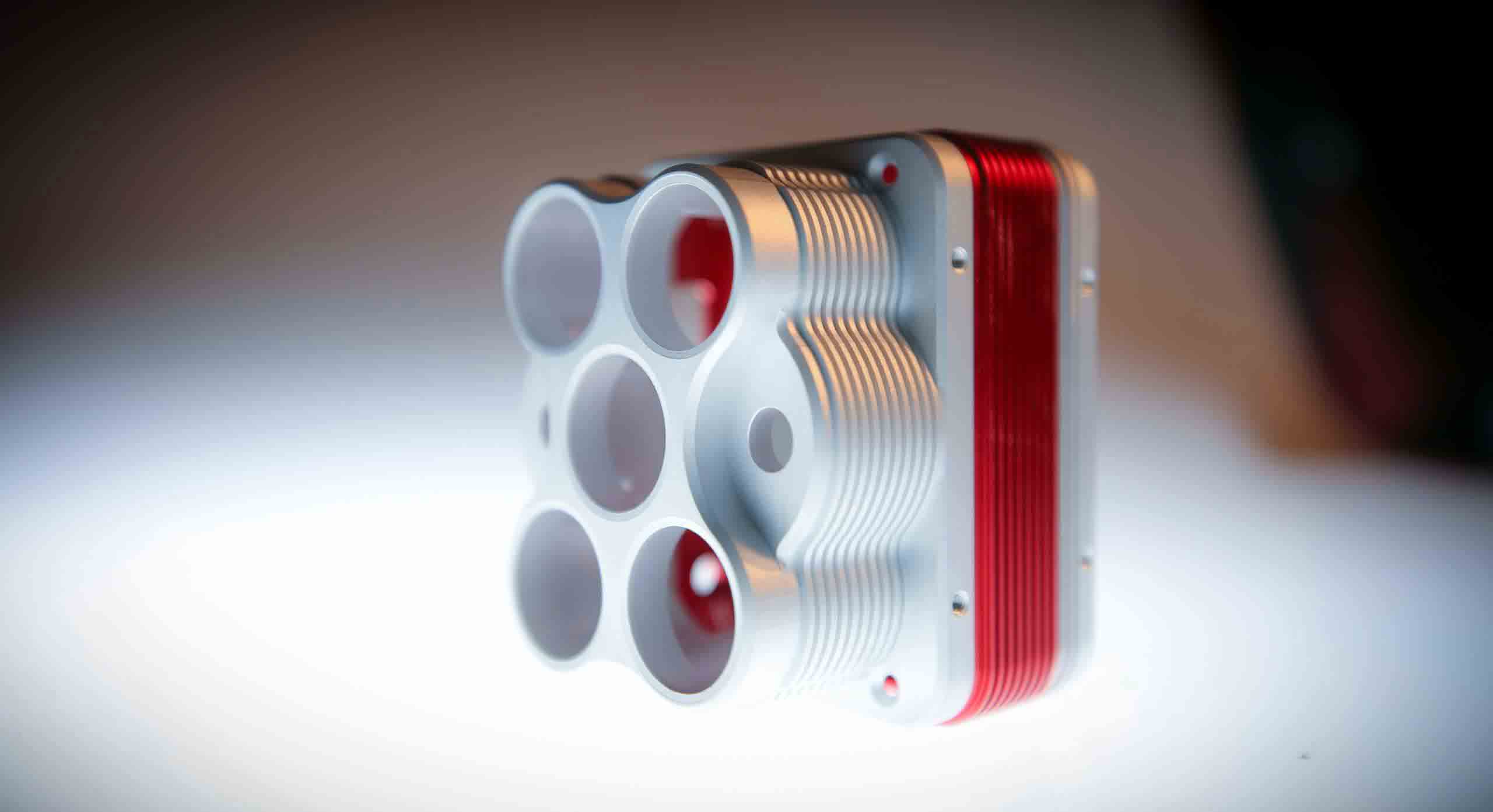

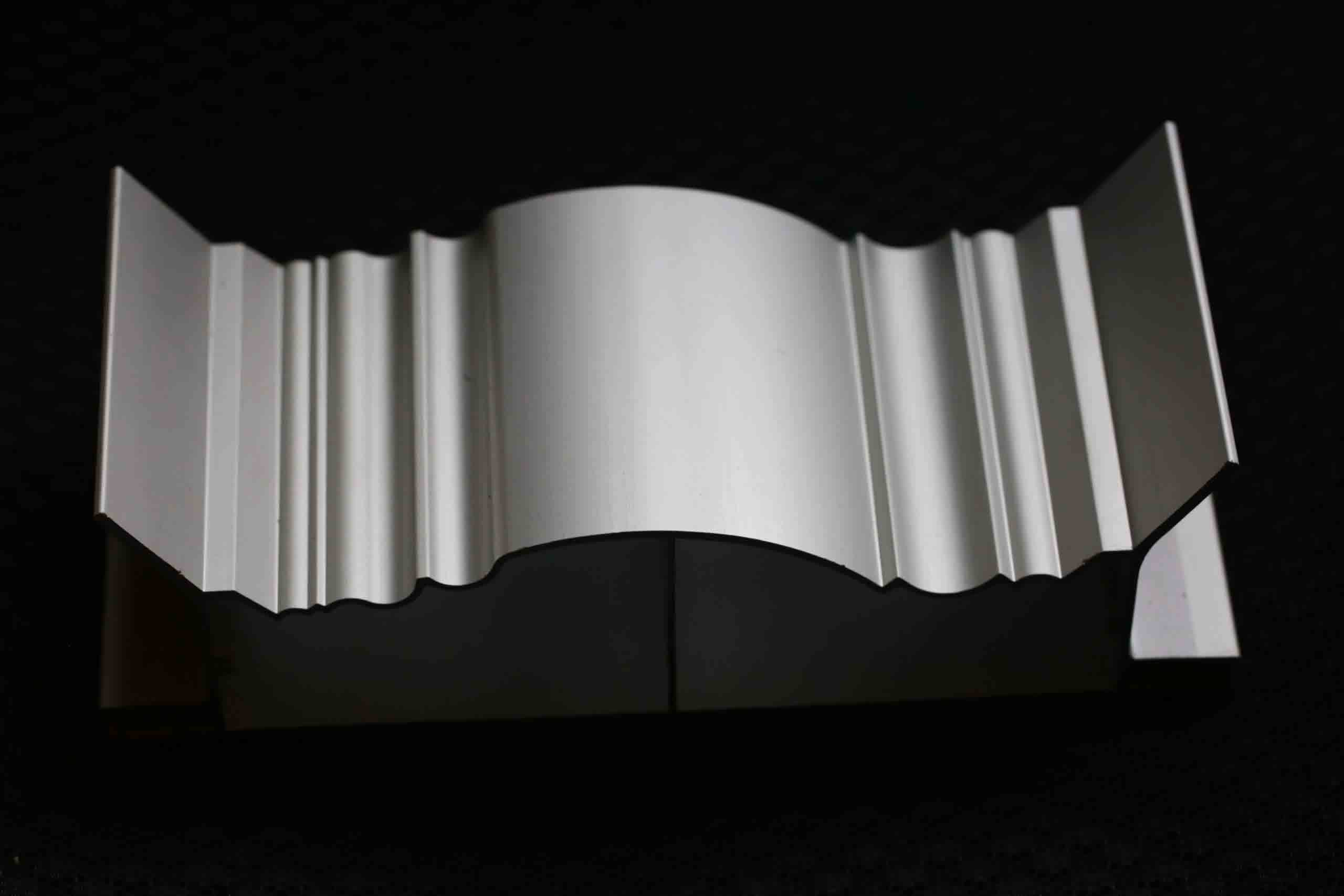

Our advanced machinery allows us to make box-section and open-channel dies with dimensions ranging from 185 square millimeters up to 275 x 60 millimeters. We can also make complex extrusion profiles with finished lengths up to 5 meters.

To complement our aluminum extrusion services, we also provide multi-axis CNC post-machining services, such as hole drilling and tapping. Wire EDM is also available for short-run orders that don’t need a dedicated extrusion die.

On-Time Delivery with Tested Performance

Working to complete projects on-time and on-budget, we have 2- to 48-hour response times on RFQ’s 95% of the time, as well as a 90%+ OTD (on-time delivery) against our commitments. We also have robust quality control and quality assurance processes, which help ensure that our finished products work the way they’re supposed to.

Investment That Matters

We’re passionate about our people and processes, which is why we’re always investing to improve them. We’ve implemented a Star University program of mentorship and training to ensure our personnel have the skills they need to be the best in the business. And we are always upgrading our facilities and equipment to stay at the forefront of advanced manufacturing.

Related Blog Posts

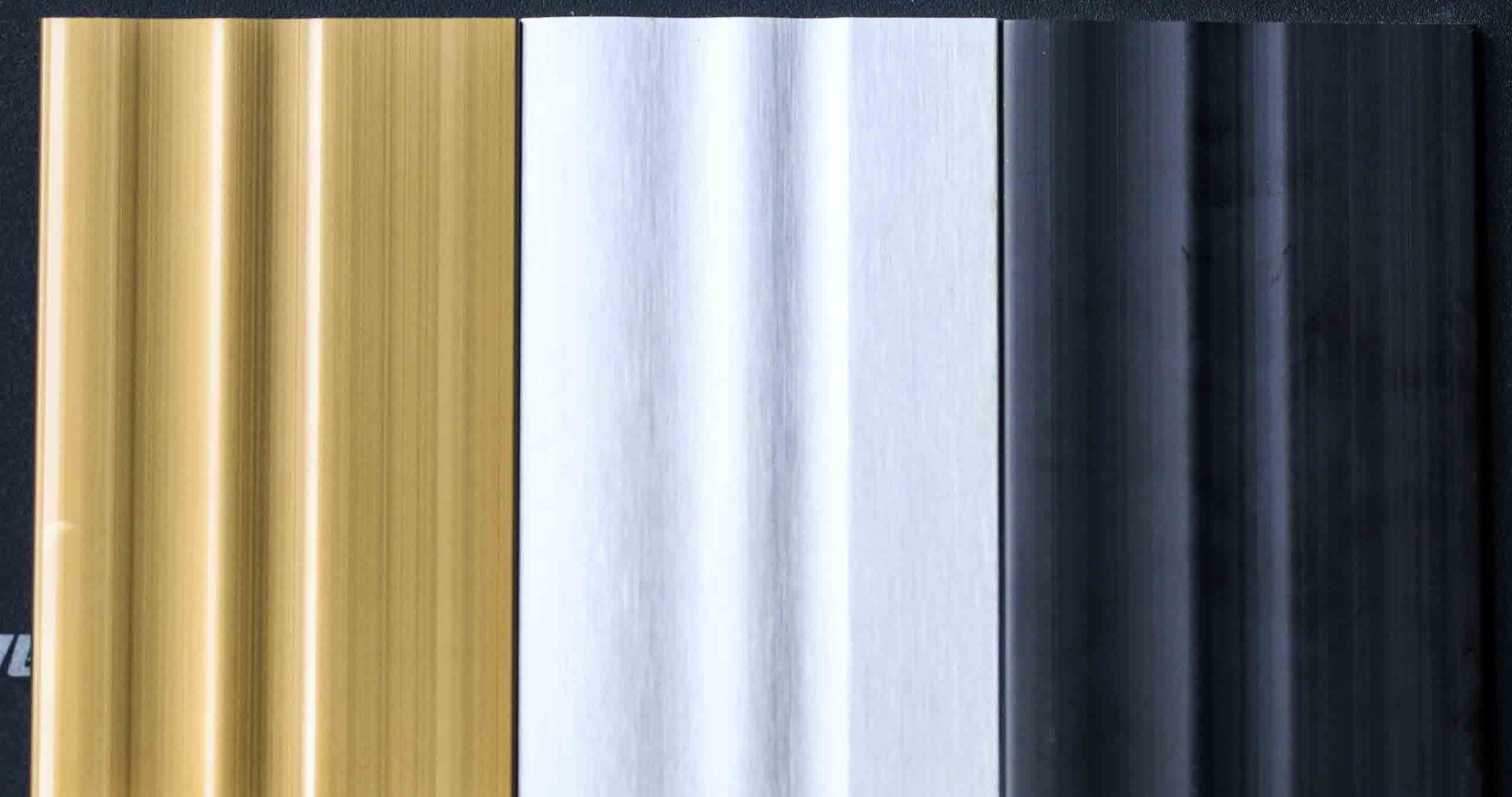

8 Things You Need to Know About Anodizing Aluminum

Anodizing is a method for changing the surface chemistry of metals and other substrates. It protects against corrosion, enhances aesthetic qualities, resists scratching and is one of the most durable surface finishes available. Anodizing can be done on a range of materials, but today let’s look at aluminum. These 8 questions will help to show why anodizing is a clever surface treatment that’s both practical and beautiful.

How To Choose The Right Material for CNC Machining

There are hundreds of metal alloys available for CNC milling and turning. Which one is best for your next project depends on a number of factors, including price, workability, corrosion resistance, strength, weight and cosmetic appearance. To help you choose, here’s a closer look at the ones we use every day and what benefits they may have for your next project.

What Does Michigan CNC Machining Parts, Inc. Offer?

We make box-section and open channel dies in sizes ranging from 185mm2 up to 275 x 60mm. These dies produce complex extrusion profiles in finished lengths up to 5 meters.

We also offer Multi-axis CNC post-machining including hole drilling and tapping. Wire EDM is available for short-run orders of complex profiles that don’t require a dedicated extrusion die.

We control all post-processing operations according to your exact specifications. This includes polishing, anodizing, painting and powder coating to complete your parts.

Aluminum Extrusion Tolerances

We follow the standard general NADCA tolerances. However, if your requirements are very precise, then the precision tolerances standard can be followed once we have confirmed your designs.

Specifications

Press sizes: 450T ~ 3000T

Minimum order volume: 0.5 ton aluminum for smaller machines, 1.0 ton of 6063 aluminum for larger machines.

Tooling lead time: 2 weeks for small molds, 4 weeks for larger molds.

Post-machining: Full service CNC cutting, threading, slotting, face milling, etc.

Get Your Aluminum Extrusion Project Started Today

Our engineers are ready to work with you to make sure you get great parts fast. When you submit your 3D design files, we will consult with you to ensure design for manufacturability in order to get parts that meet and exceed your expectations. Contact us for your free quote and design review today.

Further Reading

Always striving for superior results in pressure die casting, our team here at Michigan CNC Machining Parts, Inc. has earned several accolades for our manufacturing work. Most recently, we were named a winner of the 2017 BUILD Magazine Engineering Excellence Awards alongside our client, Gate Labs. The basis for our award was the Gate Smart Lock, the first all-in-one solution for home access. Equipped with a camera, microphone and cutting-edge hardware and software, the Gate Smart Lock connects with a user’s smartphone to allow entry while also enabling those indoors to communicate with visitors. Read this short post to learn more about how we developed the award-winning Gate Smart Lock with pressure die casting. Read more…

Anodized Aluminum Colors: Understanding Color Matching

Anodizing is a great way to put an attractive and physically durable finish on aluminium parts. Anodizing improves corrosion resistance, surface hardness, prevents scratching and is an ideal foundation for painting, glue or powder coating.

There are many challenges when trying to match colors on anodized parts. Some of these challenges come from the process itself, and some are a result of the metal alloy being used.

Product developers need to know about the key factors that affect color consistency and color matching in Type II anodizing for aluminum. Read More…

A world-leader in rapid prototyping for clients in a variety of industries, our team at Michigan CNC Machining Parts, Inc. has built our international reputation through exceptional quality and service at competitive rates. In this post, we dive into the details of one of our most successful international projects: the production of Scholl’s 2-in-1 Hard Skin Remover. Designed and developed by DCA Design International Ltd., Scholl’s 2-in-1 Hard Skin Remover is a handheld tool designed to soften hard skin with a rollerball at one end and remove it with three circular stainless steel safety blades on the other end. Tasked with producing 3,000 full production quality sets for pre-production testing and trials, we manufactured a suite of tools that include polished NAK 80 steel and soft P20 steel. Learn more about our process in this postRead more…