Why Choose Michigan CNC Machining Parts, Inc.® for Finishing Services?

When it comes to your product, performance is vital — but the finishing touches can make all the difference. Michigan CNC Machining Parts, Inc. proudly offers an extensive selection of professional finishing services to supplement our manufacturing processes, giving you everything you need for a standout prototype or market-ready product. Here are just a few reasons to choose our team.

Industry-Leading Expertise You Can Trust, No Matter Where You Are

Our engineering and project management specialists have several centuries of combined experience in all areas of manufacturing. Plus, we own and operate our own state-of-the-art facility in Asia, which allows us to take on finishing services for clients across the globe.

An Extensive Selection of Finishing and Manufacturing Services

No matter what kind of product you’re developing, Michigan CNC Machining Parts, Inc. has the finishing services you can count on to make it come to life. Our finishing services include:

These services stand alongside our full suite of manufacturing capabilities, which include CNC machining, plastic injection molding, metal 3D printing, vacuum casting and more. For full-service manufacturing — from start to finish — we have you covered.

Quality and Efficiency You Can Count On

While deadlines are always a concern in the product development journey, you don’t want to sacrifice quality along the way. At Michigan CNC Machining Parts, Inc., we never do. We have 2- to 48-hour response times on RFQ’s 95% of the time, as well as a 90%+ OTD (on-time delivery) against our commitments. As far as quality goes, we’ve provided successful finishing services on thousands of products across several industries. Check out our Case Studies page to learn more.

Investment to Improve

We’re passionate about our people and processes, which is why we’re always investing to improve them. Our Star University program offers mentorship and training opportunities so our personnel can develop the skills they need to become the best in the business. And when it comes to our equipment, we are always upgrading our facilities and equipment to stay at the forefront of advanced manufacturing.

Surface Finishing Video | Michigan CNC Machining Parts, Inc.

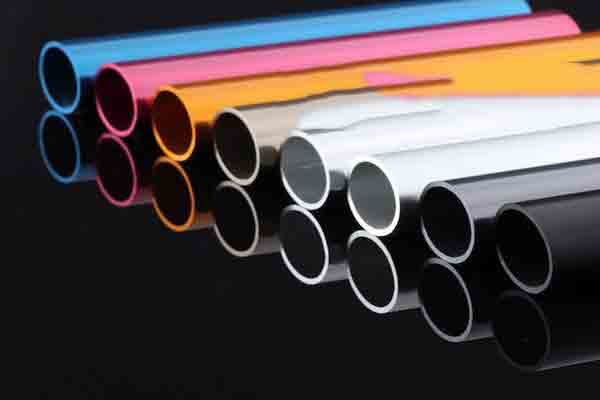

Anodizing

There are many reasons to choose anodizing on aluminum, magnesium or titanium. Anodizing helps to resist corrosion, increase surface hardness, improve resistance to wear and dissipate heat. Anodizing is an ideal surface treatment for painting and priming, and it looks great too.

We normally use Type II anodizing, which allows us to add tints or dyes to your parts for a variety of visual effects. Type III is also available for surfaces that need to be extra hard.

Anodizing Aluminum And Titanium

Painting

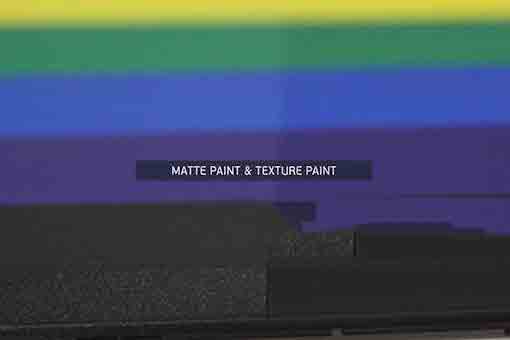

A great paint job is one of the best ways to make your product stand out from the crowd. Using only the finest PPG automotive polyurethanes, we can replicate virtually any color, tint or hue in our climate-controlled, automated spray room.

Our master painters can supply millions of colors, in matte, flat, semi-gloss or glossy finishes. We even create custom painted textures. We also have the highest ISO and BS certifications for quality and environmental protection so you can be rest assured that you’ll receive only the most professional and responsible painting service.

High Gloss And Matte Paints

Soft Touch Paint

Texture Paint

Color Matching

How can you be sure you get exactly the color you want? We can match any standard Pantone® or RGB color that you specify using our color mixing system. If you prefer, send us a sample part and we’ll use our X-Rite color tester to match it precisely. The X-Rite allows us to send color data to you wherever you are in the world and in real time, eliminating any guesswork. And our color-balanced viewing booth helps us to monitor our work so you get consistent results from one batch to another.

PANTONE® and other Pantone trademarks are the property of Pantone LLC. PANTONE color identification is solely for artistic purposes and not intended to be used for specification.

Michigan CNC Machining Parts, Inc. Painting Facility

Printing and Etching

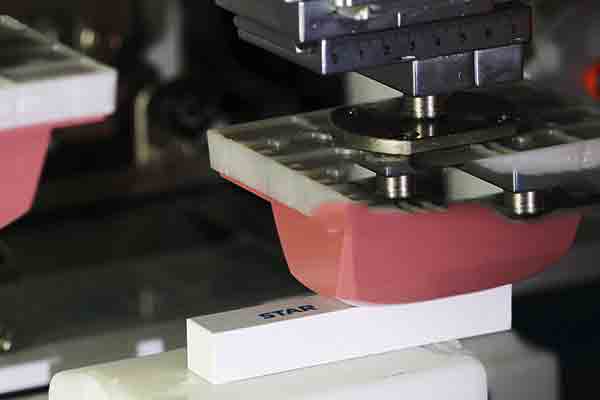

We have many ways to provide custom printing and marking of text and logos on your parts. We make custom stencils for pad printing on most flat or curved surfaces. Pad printing is fast, reliable, consistent and comes in many colors. Silk screening is also available for larger surfaces and when mixing multiple colors for even more complex graphics.

We can etch or engrave your graphics using an engraving tool, while laser etching is ideal for making the most precise and permanent marks on metal and and some plastics.

Pad Printing In Custom Colors

Sanding And Polishing

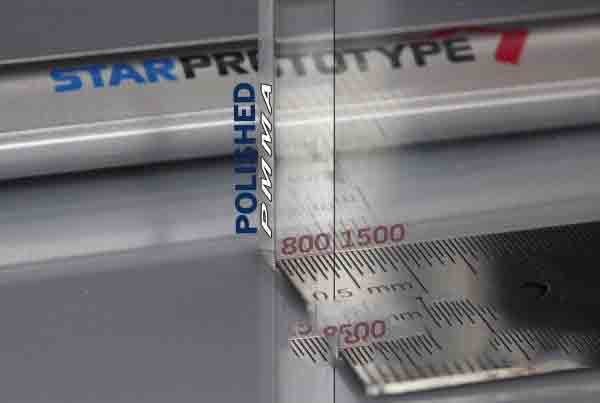

We take great care to offer the most professional finishing service for your prototype and production needs. This often involves fine hand sanding in a variety of grits to prepare your parts for later painting and plating.

Sanding is not just used for painting prep but to create the final surface finish. We can provide brushed and satin surfaces for a variety of metallic effects, and optically clear polishes on transparent acrylics. All of our work is done in a clean, well-lit, environmentally controlled model shop.

Aluminum Sanding

ABS Sanding

PMMA Polishing

Aluminum Polishing

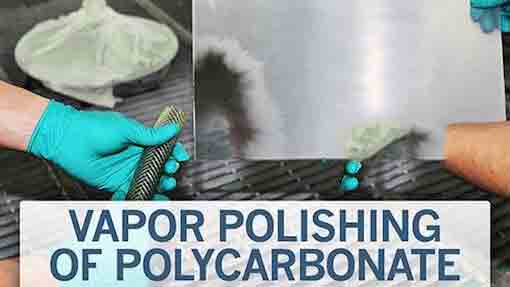

Vapor Polishing

This is a specialized treatment we do in-house for achieving optical clarity on polycarbonate (PC) plastic. This method can also be used for repairing minor surface defects, and is ideal for achieving an extremely clear surface on complex geometries or hard to reach areas.

After carefully preparing the part with sanding up to #1500 grit, it is then placed in an atmospherically controlled environment. Weldon 4 gas is used to melt the surface of the plastic at the molecular level, which rapidly reforms with all microscopic scratches blended out.

Vapor Polishing Polycarbonate Plastic

Vapor Polished Part

Vapor Polishing Process

Blasting

Blasting involves the controlled spraying of an abrasive media against the surface of your part. A variety of media can be used, including sand, garnet, walnut shells, water or metal beads.

Blasting is used to clean and deburr parts, preparing them both mechanically and chemically for later surface finishes. Blasting also imparts unique textures, frosting, pebbling, etc. Check out our blog to learn more about other popular methods for finishing a metal surface.

Sand Blast Finish

Get Your Project Started Today

Still haven’t found the type of finish you want? If you have any other special requirements we pride ourselves on finding solutions for any of your custom needs. Contact us today for a free quote to get your next project started.