Manufacturing Solutions for Medical Devices

At Michigan CNC Machining Parts, Inc., we provide custom rapid prototyping and volume production services that are able to meet the unique needs of the medical industry. We pride ourselves on delivering fast response times, strict material verification and rigorous quality control at every stage of the manufacturing process.

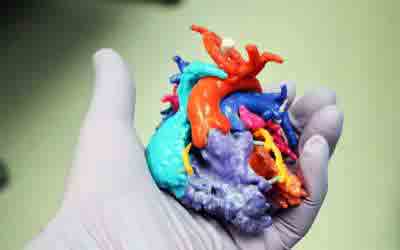

The medical industry relies on customized product solutions made to the highest standards. With a range of service offered in-house including 3D printing, plastic injection molding, CNC machining, polyurethane vacuum casting and a host of finishing services we can offer the customization and flexibility you need when building prototypes and parts quickly and accurately.

Applications we’ve made include fitness trackers, health monitors, drug delivery devices, enclosures and cases for medical devices, prosthetics and a range of other medical equipment. Another benefit is that we have no minimum order requirements and are adept at ramping up volumes from single prototypes to new product introduction and beyond.

Get to market faster by contacting us to see how we can help you manufacture your medical components.

Healthcare Companies We’ve Worked With

Why Work With Us

ISO 13485 Certification for Medical Device Manufacturing

Raw Material Testing and Verification

Design for Manufacturing (DFM) Analysis for Every Inquiry

Rigorous Quality Control at Every Step

What Our Customers Are Saying

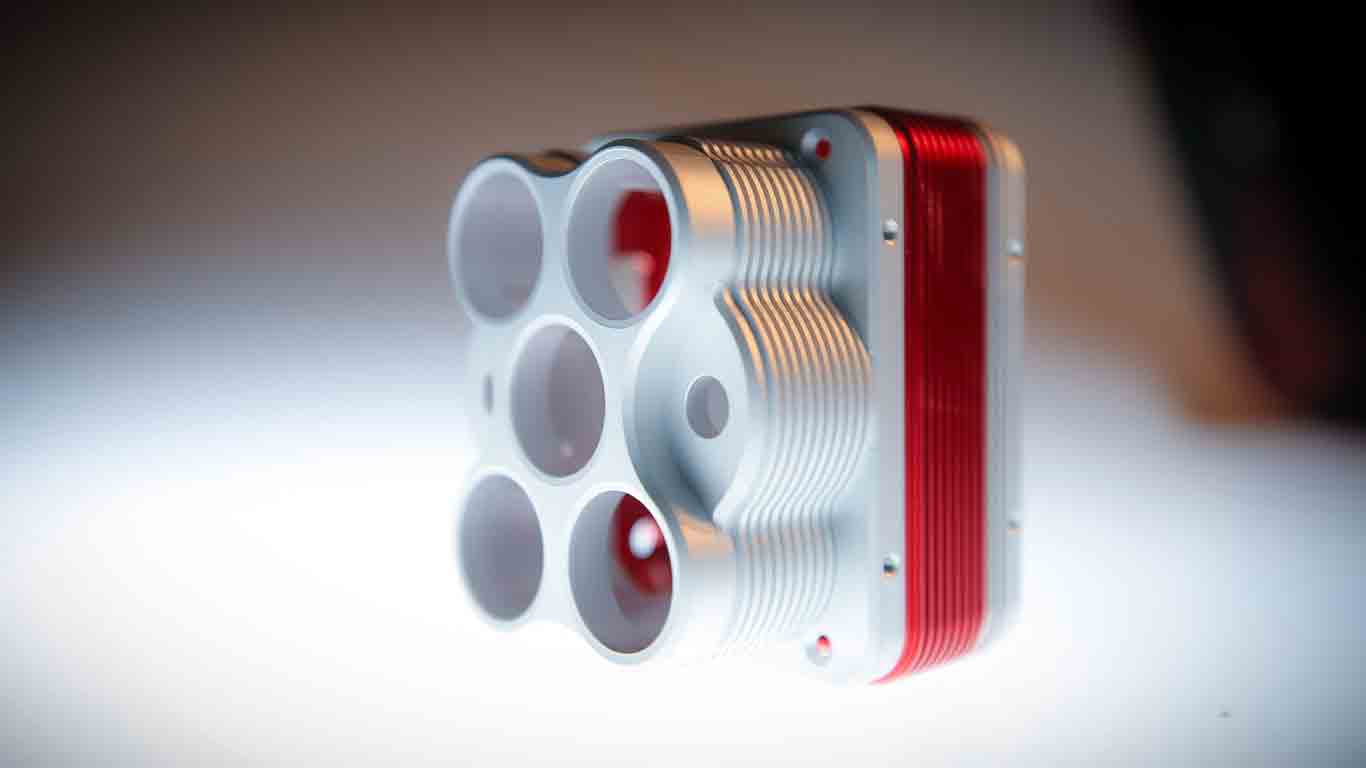

Common Medical Devices and Components We Produce

Handheld Devices

Wearables

Cases and Enclosures

Prosthetics and Maxillofacial

Drug Delivery Devices

Diagnostics

Quality You Can Trust With Inspection & Material Verification

Ensuring the reliability of the supply chain is critical in the medical industry. That’s why we use advanced metrology equipment to verify all incoming raw materials and will provide you with chemical analysis and full certificates of compliance for your peace of mind. To support the needs of the medical industry, we offer a range of materials including titanium, stainless steel, TPE, POM, PEEK, ABS, nylon, silicone rubber and more.

Our facility is fully certified to ISO 13485:2016, 9001:2015, 14001:2015 and 45001:2018 standards.

Medical Quickfacts

What are common medical applications?

- Fitness trackers, health monitors, drug delivery devices, enclosures and cases, equipment, prosthetics and more

What materials are best for medical applications?

- Titanium – Biocompatible for internal joints and skeletal replacements. Light, strong, can be 3D printed, corrosion resistant.

- Stainless Steel – Excellent for surgical instruments

- Nylon and ABS – Good for medical appliances, inexpensive, can be 3D printed in the field for emergency medicine

- TPE and Silicone – Seals and fittings, useful for custom fitting, comfortable for applications against the skin surface, chemically resistant

- POM and PEEK – Engineering-grade plastics. Strong, durable for joint replacements. PEEK can be high-heat sterilized.

Common Medical Manufacturing Services

Plastic Injection Molding

Our in-house services are suited to produce fast turnaround injection molds from a variety of tool steels. We offer reliable and repeatable results when making components and enclosures from medical and food grade plastic resins. We also do insert molding, overmolding, 2-part molds and more to facilitate your most demanding medical applications at higher volumes.

Polyurethane Vacuum Casting

Production-quality resin copies are formed from reusable silicone molds based on a 3D-printed master model. Our polyurethane vacuum casting services use pourable resins that mimic the look and feel of injection molded plastic. Cast copies are perfect for rapid prototyping, product development, modeling, testing and certification.

CNC Machining

Multi-axis CNC machining is great for making unlimited volumes of precision parts with engineering grade plastics and metal. No fixed tooling is required and design modifications can be done quickly and easily to facilitate rapid product development. This is critical for meeting the needs of a fast moving industry with short lead times, tight tolerances and a high mix of parts.

Metal 3D Printing

Our service fuses powdered metal into fully dense parts that can be designed with features that are impossible to make by other processes. This service is suitable for customized prosthetics, maxillofacial bone structures, dental appliances or artificial replacement joints. Metal 3D printed medical appliances are lightweight, strong and fully bio-compatible.

Medical Manufacturing Blogs

Additive Manufacturing for Medical Applications

Additive Manufacturing for Medicine and Healthcare The use of additive manufacturing applications is on the rise, with the market value expected to increase from $6 billion in 2017 to nearly $26 billion by 2022. The advantage of additive manufacturing comes...

The Top 5 Design Tips for Medical Products

As we all know, devices used in medicine and healthcare must meet the highest standards of performance and reliability. This is as it should be, but medical products are more than merely practical tools or appliances. Although there are many different types and...

The Six Benefits of ISO 13485:2016 For Product Developers

What is ISO 13485:2016? ISO 13485:2016 is a quality system management standard. It's similar to ISO 9001, but has a few more stipulations to help companies meet the more specialized demands that come with making medical components and healthcare related products. This...