What Separates Michigan CNC Machining Parts, Inc.’s Inspection Processes from the Rest?

Careful measurement, inspection and testing are necessary to ensure the conformance of your parts. We perform multiple inspections at every step of the product development journey, from incoming material verification to final 3D scanning. You will receive complete digital files and Certificates of Compliance so you can meet your own regulatory and performance goals.

An International Team with Unparalleled Experience

Quality inspection relies not only upon using advanced digital equipment but also having highly trained personnel with years of experience. As parts become more complex and tolerances more demanding for advanced applications, precision measurements conducted by professionals are the only way to ensure perfection.

Inspections and Review for Every Stage of Production

To ensure quality from start to finish, Michigan CNC Machining Parts, Inc. provides the following inspection and review services:

- Extensive incoming materials verification

- Design for manufacturing reviews for all quotes provided

- Contract reviews upon receipt of POs

- First article and in-process inspections

· Final inspections and testing with reports and certifications as required

ISO Certification and Visual Quality Standard

Committed to the continual improvement of our industry-leading quality control and quality assurance processes, we are fully certified and compliant with ISO 9001:2015, ISO 14001:2015 and ISO 45001:2018 in addition to ISO 13485:2016 for medical products.

To ensure the highest level of aesthetic appeal alongside performance, we perform a visual quality inspection under controlled lighting and environmental conditions to confirm cosmetic appearance according to your specifications. Additionally, we have a Visual Quality Standard for our plastic injection molding services to ensure that our parts are consistent with one another and look exactly the way you want them to.

Cutting-Edge Inspection Equipment

To conduct our extensive range of inspections, we use a wide variety of advanced equipment, including:

· Bruker Alpha II FTIR Infrared Spectrometer

· PolyMax Gun

· Oxford Instruments and Hitachi Optical Emission Spectrometers (OES)

· Oxford Instruments XRF Analyzer

· Zeiss Comet L3D 2 Optical Scanner

· SmartScope ZIP Lite 300

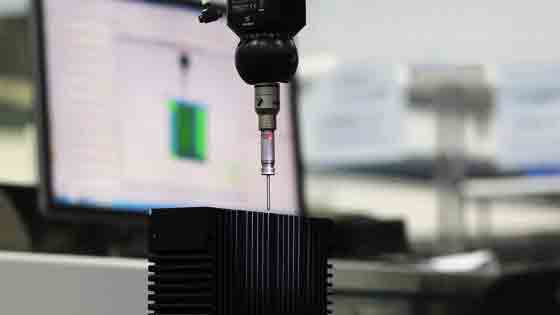

· Nikon Coordinate Measuring Machine (CMM)

· Mitituyo Profilometers

· X-Rite Spectrophotometer

Investment in Inspection

We have over $1 million invested in inspection and testing equipment, as well as a climate-controlled inspection department that helps us guarantee uniform conditions for maximum accuracy and repeatability. We stake our reputation on our ability to provide the best quality assurance services in the industry.

When it comes to inspection, the results speak for themselves. To learn more about some of our many successful manufacturing projects, visit our Case Studies page and see our inspection in action for yourself. Have questions? Ready to obtain your quote? Contact us

In-House Incoming Material Inspection Equipment

Making products with consistent high-quality requires good process control techniques combined with advanced equipment. At Michigan CNC Machining Parts, Inc., we have advanced inspection measuring and testing equipment in-house to qualify all incoming raw materials. We perform plastics and metals testing and offer Positive Material Identification (PMI) for all incoming materials so you have complete confidence you receive exactly what you ordered.

Bruker Alpha II FTIR Infrared Spectrometer

The Bruker Alpha II FTIR Spectrometer is the newest addition to our metrology and testing lab for qualifying incoming raw material. With this tester, infrared radiation is used over a broad spectral band to verify plastic samples with a degree of accuracy higher than 97%. Very few other suppliers go to such lengths to ensure that our material is completely in conformance with your specifications.

PolyMax Gun

There are many thousands of available plastic resins to choose from when making plastic injection molded parts. In order to ensure that the resin we use is of exactly the right kind, we’ve invested in a PolyMax analyzing gun. This device uses a beam of laser light to bounce off the surface of a test sample and read the unique signature given off by its molecular vibration. It contains a database of hundreds of plastic types in memory, and can be programmed with additional plastic types whenever the need arises. Just one more way we’re staying ahead of the competition to give you exactly the right material every time. And check out our blog to read more about how the PolyMax gun works.

Optical Emission Spectrometer (OES)

A testing apparatus that uses a current to electrically charge a sample of the material. The resulting discharge of plasma is unique for each element and this pattern can be read by the optical spectrometer to determine the metal’s complete composition.

There are many similar alloys and grades of metal available on the market, and some of them are mislabeled or fraudulent. We offer Positive Material Identification (PMI) for all incoming materials so you have complete confidence that you receive exactly what you ordered. We are one of the few services in China to offer this level of testing.

XRF Analyzer

X-Ray Fluorescence (XRF) analysis is a non-destructive testing (NDT) process by which materials such as metals, clothes, plastics, ceramics, etc. are exposed to low level, short-wave X-rays or gamma radiation. Each element reflects the emission with a different wavelength and a specially calibrated spectrometer can analyze the wavelengths to detect what elements are present and in what relative concentrations. The XRF analyzer can also detect banned materials under the REACH and RoHS legislation.

Final Part Inspection Equipment

Using our Zeiss Comet L3D 2 Optical Scanner, SmartScope ZIP Lite 300, Nikon Ultra Coordinate Measuring Machine with Renishaw Probes, X-Rite Spectrophotometer and more, we are able to perform manufacturing quality control and ensure the parts we manufacture matches your design specifications. At Michigan CNC Machining Parts, Inc., the Final Inspection department is a crucial part of our ISO certified manufacturing facility. We’re committed to continuous quality improvement, respect for our workers and for the environment.

Zeiss Comet L3D 2 Optical Scanner

The Zeiss Comet L3D 2 optical scanner is a portable, state-of-the-art scanning system for capturing and computing 3D data quickly and with a high degree of precision. With easy to use software and interchangeable lenses and sensors, the Zeiss Comet can scan up to five million data points on parts of almost any size within its wide focal range. This is ideal for checking parts for conformity, identifying manufacturing errors and reverse engineering. Just part of our commitment to total quality control.

SmartScope ZIP Lite 300

The SmartScope ZIP Lite 300 is a non-contact optical measuring system using a high intensity white LED light for fast and accurate 2D measurements of parts. High-precision mechanical bearings and DC stepper motors, mounted to a solid granite base, ensure reliable and repeatable precision. Coupled with sophisticated but easy-to-use Measure Mind software, the SmartScope can be quickly programmed to run automated measurements of multiple similar shapes.

Coordinate Measuring Machine

At its most basic a coordinate is a point, a fixed singular location in three-dimensional space. A series of points can be used to define the parameters of a complex shape. Therefore a coordinate measuring machine (CMM) is any device that is able to collect this set of points for a given object and to do so with an acceptable degree of accuracy and repeatability.

Surfometer

Our Mitutoyo Surfometer measures the surface roughness of an item, so we can ensure a specific surface finish is achieved. This device is also portable for greater convenience for our clients.

X-Rite Spectrophotometer

The X-Rite spectrophotometer is an analytic device that we use to verify the color of your parts. By reflecting a light source off of the target surface and comparing this to a standard, we can determine the precise numerical value of your color sample. This information can then be sent to you directly for confirmation, and is also used by our production team to monitor and control our manufacturing process for your complete satisfaction. You can read more about the process in our blog.