The human body is a marvel of engineering, a wonderment of complexity, subtlety and adaptation. But we are still prone to the ravages of time, injury and disease, and we turn to the world of medicine to help fix whatever ails us. Now we may also be turning to engineers and model makers to get some of those new replacement parts we need to get back out on our feet and into the world.

Rapid prototyping and 3D printing continue to expand their reach into all aspects of our daily lives and now they offer incredible new opportunities for improving human health and assisting doctors in doing what had previously been unthinkable. Here are just some of the latest advances in medical applications for 3D printing technology.

Rapid prototyping and 3D printing continue to expand their reach into all aspects of our daily lives and now they offer incredible new opportunities for improving human health and assisting doctors in doing what had previously been unthinkable. Here are just some of the latest advances in medical applications for 3D printing technology.

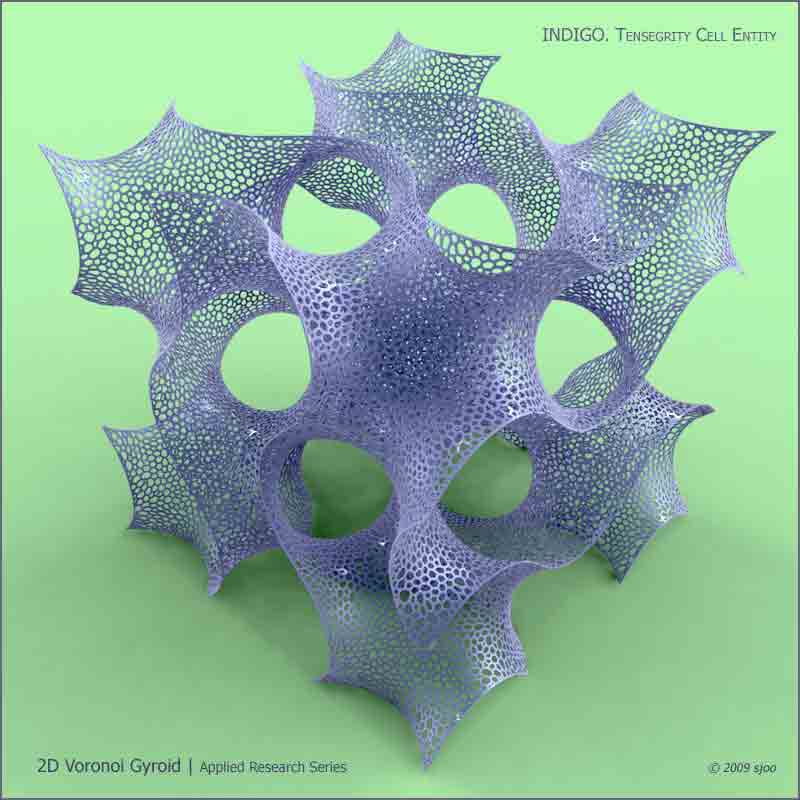

Human organs can be divided into four major categories, depending upon their geometrical complexity. The simplest form is a flat surface, like skin. Then there are tubes, such as blood vessels. The stomach or intestine is an irregular, empty container, while the heart and lungs are solid shapes filled with cavities, and are thus the most difficult to replicate.

It’s now possible to lay down fine layers of human cells onto a nutrient matrix, printing relatively simple patches of skin. Molds are also used as a foundation on which can be grown an ear, for example. Now doctors at the Wake Forest Institute for Regenerative Medicine have created a functioning human bladder, by taking a patient’s own cells and placing them, layer by layer, over a 3D mold and then incubating that new tissue in an environment that simulates the conditions of the human body. And Harvard University is now “printing” skin cells with functioning, embedded blood vessels that rely upon a latticework scaffolding to maintain their shape as they’re formed.

The making of prosthetic limbs used to be the provenance of specialized artisans, who would craft each piece for the unique anatomy of the user. Now laser scanners can map out, for example, a person’s intact and healthy right arm and use that as the basis for drawing a reverse-image left arm in precisely the right size and shape. This drawing can be sent to a printer and, with readily available materials, a new prosthetic arm is easily printed and put to use. And as 3D printers become smaller and more portable, they’re now being brought into the field, in war-torn or impoverished areas all over the world, to alleviate suffering for those lacking access to a major hospital or rehabilitation center.

A researcher at the University of Washington modified a 3D printer to apply a ceramic powder and chemicals together to form a framework for building artificial bone. Right now the material can be used for low load-bearing applications, but in the future it’s hoped that the natural degradation of the ceramic material can be combined with bone-regenerating drugs to allow real bone to slowly grow into, and displace, the artificial bone without harm to the patient.

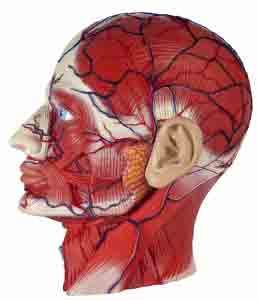

Last year in China a farmer named Hu was working on a construction project on his home when he fell and a pile of wood landed on his skull, badly crushing in one side. Although still alive and ambulatory he can no longer speak and suffers other lasting effects. A team of doctors in Xi’an used a 3D printer to create a customized titanium metal mesh to reproduce the skull’s original shape. If the graft is accepted, it’s hoped that the damaged brain tissue may be able to grow within the new cavity and help to restore some lost functionality.

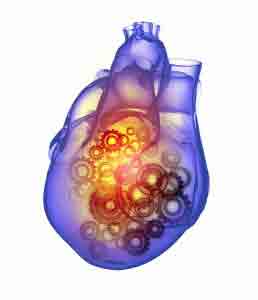

Given all of these new capacities, the making of medical devices like clamps and stents is relatively simple. But along with heart valves and pumps, a new technique is now being developed that could be the most radical innovation of all. Imagine a 3D model of a human heart, taken directly from a CT or MRI scan of the patient. Onto the mold is affixed a flexible, skin-like membrane. Cells from the patient are printed onto the mold layer by layer, but with the addition of an embedded fabric mesh filled with wires and electronic sensors. This new membrane is that implanted over the patient’s heart, and the sensors provide real-time information about heart rate, blood flow, oxygen uptake and anything else necessary. We talked about the Internet of Things. In the future it may be easier than ever for your care provider, or their computer, to monitor your vital health and to even dispatch emergency services automatically should the sensors register a crisis – all without human intervention.

3D printers on the battlefield to craft replacement tissue or limbs? Printers in the home to make custom medicine and other chemicals? 3D printed teeth in titanium or stainless steel? It’s no longer science fiction but is happening now. How far can it go? We’re not sure but check back regularly and we’ll keep you posted.

Chris Williams is the Content Editor at Michigan CNC Machining Parts, Inc.. He is passionate about writing and about developments in science, manufacturing and related technologies. He is also a certified English grammar snob.