The unprecedented challenges people are facing around the world due to the novel coronavirus outbreak are straining every aspect of modern life. But many innovative companies are meeting these challenges by leveraging technology and information to create solutions in record time. Here is a look at what is happening now and coming soon.

Ford, GE Healthcare and Airon to make 50,000 Ventilators

Ventilators are essential for providing oxygen to patients who cannot breathe independently. There is a critical shortage of these devices that will only get worse in the days ahead. To meet this demand, Ford, GE Healthcare and Airon have teamed up to combine Ford’s now-idled automobile manufacturing capacity with GE’s expertise in clinical devices. Airon is a small Florida-based device manufacturer that already has a joint FDA license with GE Healthcare. This will make the certification process much more streamlined so these ventilators can get in the field quickly. In the meantime, Ford is also working with GE on their current line of ventilators.

Autoworkers are being re-trained to build ventilators at Ford’s plant in Michigan

Ford is promising round-the-clock production at their Rawsonville Components plant in Michigan starting from April 20th and they plan to have 50K units ready over the next 100 days. There are also similar efforts underway between GM and Ventec, among others.

Ford Joins with 3M to make Respirators

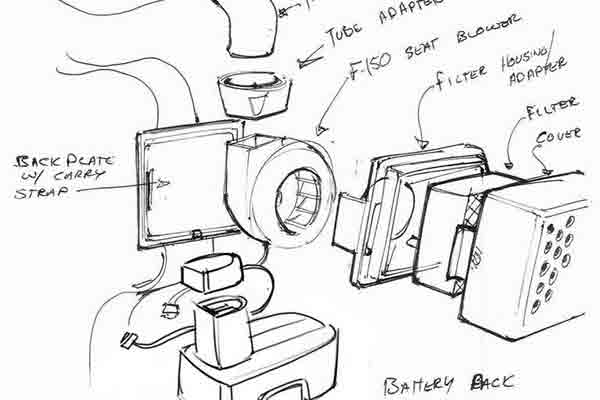

Ventilators pump air into the lungs, while respirators filter contaminants out of incoming air. Ford is working with 3M to make powered air-purifying respirators (PAPS). Ford will provide stock air fans from their F-150 trucks while 3M will provide the filters and medical expertise.

The fans are small and portable and they run off of 12 volt power, perfect for a battery pack. And because these fans are stock items they already exist in large volumes. In addition, Ford will use their 3D printing capacity to make the face masks.

Prusa Research to Make Face Shields

Prusa Research in Prague, Czech, is the largest 3D printing factory in the world, with over 1000 printers in operation. Josef Prusa and his team are working on a design for a face shield that will help augment the standard surgical face masks which are in short supply. Their simplified plastic face shield is currently being tested by the Czech Ministry of Health and the CAD design will be made available free of charge to other printing facilities once it’s approved.

These face shields are inexpensive and can be printed easily in the field

They hope to produce at least 10,000 shields before they begin working on goggles and glasses.

Dyson CoVent

The Dyson CoVent was designed in less than two weeks

James Dyson and his team of product designers have come up with a new and simplified ventilator design in just 10 days. It makes use of Dyson’s proprietary vacuum technology to provide incoming oxygen while venting exhaled CO2. The CoVent is currently undergoing approvals and they hope to soon have 15,000 available in the UK, with other markets being supplied thereafter.

Materialise Making Hands-Free Accessories

Door handles, drawer pulls and door knobs are some of the most easily contaminated surfaces. Health care professionals and other care providers may need to touch such handles hundreds of times each day. One way to prevent spreading the disease is to use the forearm – preferably covered with a sleeve – to open the door instead.

Use your sleeved forearm to avoid touching the handle

Materialise created this printable hands-free paddle design to assist with door opening. Their design is available for free from the Materialise website and can be downloaded to printers anywhere in the world where they are needed.

In addition, many consumers these days are stocking up on groceries and other necessary supplies, and that means pushing a lot of shopping carts.

These handles can be fitted to many styles of carts

These cart handles, also from Materialise, help consumers to control their shopping carts without using their hands. A simple, elegant and easy-to-use solution that perfectly demonstrates how every little bit helps in this fight. And it’s also a gentle reminder about how important it is to practice good hygiene and avoid touching surfaces whenever possible.

Rapid Manufacturing Solutions

Agile manufacturing solutions using 3D printing and other technologies can help to meet critical needs and support communities at risk. We are proud of the spirit of ingenuity and cooperation demonstrated by these companies. Be assured that Michigan CNC Machining Parts, Inc. will do the same to support your important projects when you upload your CAD files for a free quotation today. And go here to learn more about how we are responding to the coronavirus outbreak.

Chris Williams is the Content Editor at Michigan CNC Machining Parts, Inc.. He is passionate about writing and about developments in science, manufacturing and related technologies. He is also a certified English grammar snob.