As a product designer you know that your choice of a surface texture goes a long way towards determining how your product looks, feels and performs.

However, you may not realize that there’s a specialized vocabulary used by manufacturers when they make and describe surface textures. If you become familiar with these terms and how they’re applied, it can help you to avoid misunderstandings while also saving you time and money in the product development process. First let’s look at why the surface texture is important.

Why Should You Care About Surface Texture?

The texture of a solid plastic or metal part has a lot to do with its mechanical properties and function. Texture affects friction, corrosion, heat transfer, wear and many other factors. For example, very rough surfaces help to improve the grip on parts that need to be held in the hand, but would be completely inappropriate as a bearing surface.

Textures are often used creatively, such as when they’re employed to hide manufacturing defects like parting lines on plastic injection molded enclosures. Others are used cosmetically to imitate wood, stone or leather. Finally, surface texture is very important when preparing for later painting or anodizing.

What Is Surface Texture?

Surface texture, from a manufacturing point of view, refers to the three-dimensional topography of a solid. Since a perfectly flat and featureless surface topography is not possible, all surfaces therefore have some kind of texture.

Some of these textures can appear to the naked eye in the form of regular repeating patterns while others are more random or diffuse so it can be a challenge to describe them in a generally agreed upon way.

How is Surface Texture Described?

There are a few specialized terms that are used to technically describe a surface texture. Engineers and product designers should be familiar with these terms to communicate effectively with manufacturers when new products are being developed.

Lay

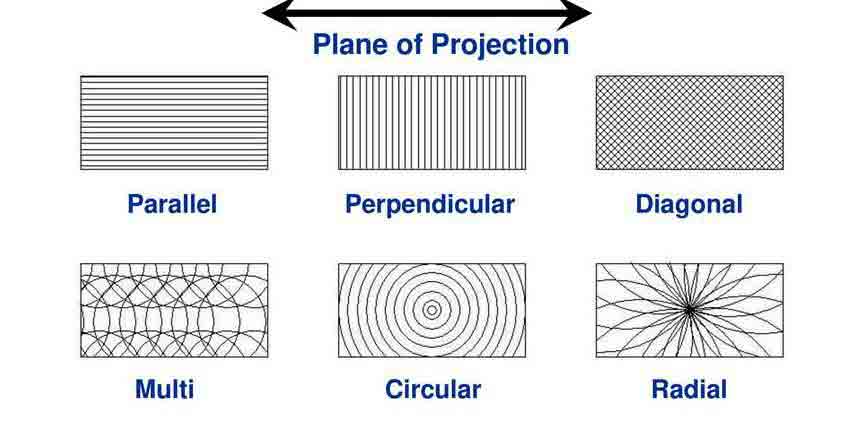

This is the general direction of a surface pattern. This is considered a large scale or global pattern created by the process that made the surface, such as milling, grinding, sanding, etc.

Here the lay is clearly indicated

Waviness

As with lay, waviness is caused by the movement of the machine tool over a large area. In this case, the waveform is a function of a cyclical and repeating vibration that is transferred to the workpiece.

Waves are indicative of short, periodic patterns due to vibration

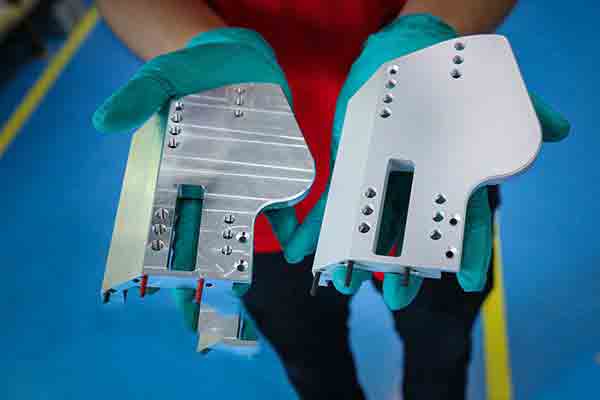

For example, the characteristic marks on this plate are typical of CNC machine tools that chip away at the surface as they spin.

Roughness

Few subjects in our experience cause more potential misunderstandings with our client partners than that of roughness and how to describe it. Roughness is at the finest scale of measurement and is caused by the interaction of the cutting tool or an abrasive at the surface in a more random, chaotic fashion.

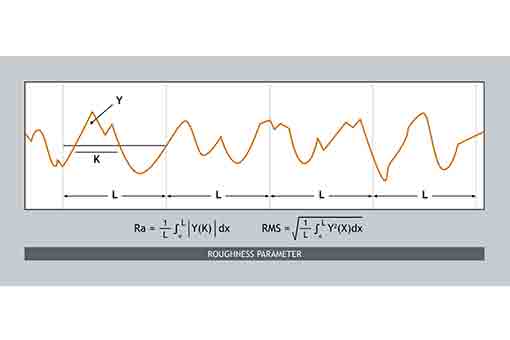

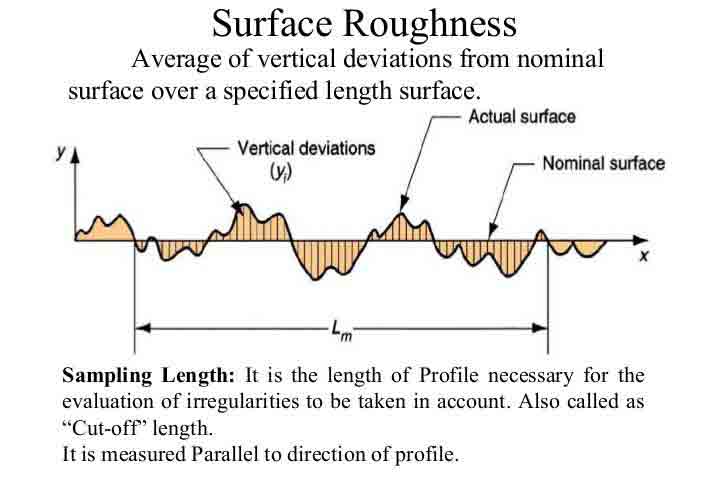

Surface profile for roughness measurement. Image courtesy of Aman Dave @ Slideshare.

Roughness is usually specified with a value called Ra. This is computed by measuring a given sample length with a fine probe or stylus called a profilometer. The sensitive tip of the profilometer is dragged across the surface of the feature, in a direction perpendicular to the lay of the texture. The stylus is able to record very minute variations. From this is calculated the average height deviation from a nominal flat line. The lower the Ra value, the flatter or finer the surface is said to be. You can learn more about how Ra works, here.

Is Ra All You Need To Know?

Remember, Ra only tells us about random, localized points above the average plane of the surface. There are many ways to manufacture a part which will achieve the same value but leave quite distinct surface finishes.

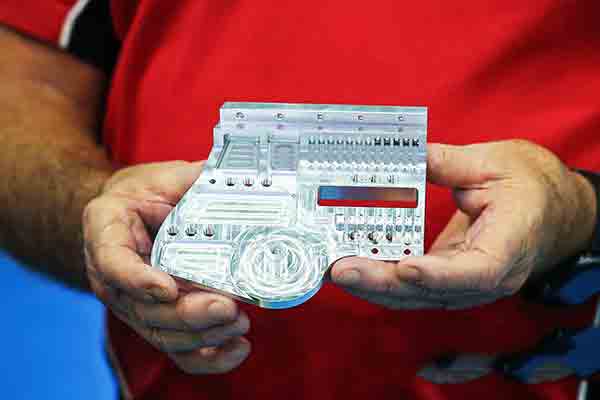

Sample patterns from manufacturing processes. Image courtesy of Wikiwand, all rights reserved.

If you have a definite pattern you need on your parts, it’s best to submit a sample for testing and we can help you to match it. We hope that this information has been useful, and if you’d like we have more advice about how to choose the right surface finish on your next project.

Chris Williams is the Content Editor at Michigan CNC Machining Parts, Inc.. He is passionate about writing and about developments in science, manufacturing and related technologies. He is also a certified English grammar snob.