Every day we talk to inventors, entrepreneurs and product designers who need help making a physical prototype. For these people to be successful inventors, they need to be armed with knowledge to avoid the many pitfalls they may face in the development process. Here are 7 tips to help make the journey easier.

1. Research Your Customers

We must assume that the product inventor is looking at a potential consumer product, not something intended for industry. If this is the case, then there is a lot that goes into determining if a product idea will be commercially successful – and even many big, established brands don’t always get this right either.

First and foremost, it requires an honest and dispassionate appraisal. The two most important questions to answer here are these:

- What problem does the product solve, or what need does it address? Virtually all successful products meet a perceived need that already exists or fills a gap in the market that is not filled by any competitor. Don’t try to create a market from thin air!

- Who is the target audience for the product? We’re not talking friends and family. Imagine complete strangers paying hard-earned money for your idea. Eventually, you or someone will need to make a persuasive case that it is in their interest to do so. Be assured that someone can make that case when the time comes, after you have a working prototype in hand.

2. Research The Market

Ensure that your product idea does not already exist in some form, or that it has not already been tried in the past and failed to succeed.

- You may need to invest in doing a patent search to confirm the uniqueness of your idea and to avoid a very costly legal battle later.

- Beware patent trolls who scoop up intellectual property and then hold it for ransom.

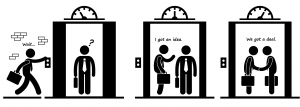

- Can you make the elevator pitch? You step into an elevator and with you is a millionaire investor. You’ve got one minute before the elevator stops to tell this person what your idea is, how it works, who will buy it and why it will be successful. If you can’t do that in one minute, it’s too complicated.

- If you have already found something similar on the retail shelf, don’t assume you can make a competitive product at the same price point. Big consumer product giants already have manufacturing partners and an established supply and distribution chain. They amortize their tooling and development costs over millions of pieces.

- Do you envision your product on a retail shelf? Careful. Retailers will charge you for every square inch of shelf space, they will charge a re-stocking fee, and if the product doesn’t sell you need to buy it back. There are ways to work with retail middlemen who will carry these costs instead of you, the lone inventor. Be prepared to be humble and realistic here.

3. Hire A Designer

Unless you’re a professional CAD designer with experience in consumer products, don’t do this yourself. Hire a professional. Consider this a necessary expense, separate from the cost of the development process itself. Only after you have a professionally rendered 3D CAD drawing in hand will you be able to then try to source a potential manufacturing partner. Lacking this, all cost estimates are doomed to be wrong by orders of magnitude and will only cause frustration and further financial dismay in the future.

We cannot stress this too much. This is the place where great ideas go to die. A bright idea in the imagination must translate to a physical object in the real world that can be manufactured at reasonable cost. Bite the bullet and pay for a designer to do this with your input. If you’re not willing to make that investment, the idea isn’t worth pursuing. Better to know that now than to find out later.

4. Make A Prototype

A prototype in hand is a great way to really test out if your idea looks and feels and works the way you imagined that it would. It will also tell you if something doesn’t fit right, needs to be tweaked or if you might want to consider a major re-design.

You’ve decided to take the next step and make a physical prototype of your idea using your spiffy new CAD drawing. You’re in luck here, because now there are more services than ever before to create a 3D object quickly and accurately. Depending on your design you may choose stereolithography, 3D metal or plastic printing, vacuum casting or CNC machining, among others. Each of these processes has their advantages and inherent costs. If you’re unsure about which to choose and why, now is a good time for your prototyping partner (Star is good!) to offer helpful and no-cost advice.

If you’re happy with your prototype, then it might very well form the basis for a crowdfunding campaign on Kickstarter or Indiegogo. Potential investors will need to see that the idea is cool, makeable, sellable and worth having. Only a nice, professional looking model or sample is going to effectively demonstrate this.

If you’re convinced you have a winner on your hands, patent it. Do it now before you proceed any further or else all your hard work may end up being for someone else’s benefit.

5. Research Your Finances

At this stage you’ve already spent some money on design and making a prototype. If you still want to continue there are some hard facts that must be faced with cold logic, but all is not lost. If you’re assured that your idea is good and marketable there are several ways to proceed from here:

- As discussed above, consider a crowdfunding campaign. These have certain restrictions, such as a limited time period in which to make your case and you won’t collect any money unless you meet your funding goal. While Kickstarter campaigns have been very successful for some, they increasingly rely on very slick and professionally produced marketing campaigns, including video and computer graphics. This is another expense to be accounted for.

- Accelerator programs have become popular among the maker community. They offer professional development advice, a communal maker space and introduction to tried-and-true manufacturing partners. In exchange, the accelerator program gets a percentage of future sales from the product. Could be a good way to lighten the financial burden, while also putting the potential inventor in touch with a lot of other like-minded people also trying to get their ideas off the ground.

- Outside investors or venture capitalist firms. They will each have their own policies and procedures, but in all cases read the fine print and don’t sign anything unless and until it has been vetted by a financial advisor or, better yet, an attorney specializing in intellectual property. Yes, an attorney is another expense and you don’t even have a finished product yet! Remember, at this stage you’re still at the mercy of other people to get your product made. Protect yourself at all costs. Money spent now will save you ten times over in the future.

- Other loans. Avoid if at all possible. You will be compelled to repay the loan at interest with no guarantee that your idea will be successful.

- Personal savings. Don’t risk anything that you’re not prepared to lose.

6. Find A Manufacturing Partner

When considering a manufacturing partner you should adhere to the following guidelines:

- Don’t show your idea to anyone until you have a signed Non-Disclosure Agreement (NDA) in hand. This may not protect you in all cases but you certainly won’t be protected without it.

- Get quotations from a number of people for comparison, but don’t assume that the cheapest price is the best! There are many factors effecting the success of your product build – price should be the last consideration, not the first.

- Before you choose a manufacturer, visit them in person first if you can. Do not rely on phone calls or emails at this stage. Check out their facilities for yourself. Bring an objective, outside interpreter with you if necessary, not someone provided for you by the supplier.

- Confirm the legal status of the facility. Ask to see their documents of incorporation, licenses, etc. If they don’t show you, find someone else.

- Ask them to show you examples of previous projects. Confirm their ability to make what they say they can make.

- Where do they get their raw materials from? Can they show you documentation proving the legal and safe origin of all raw materials in use? If they don’t, leave.

- Can you communicate with them? This is key. Do they understand your questions and concerns? Do they reply in clear, unambiguous language? Trust your instincts here. If it doesn’t feel right there’s probably a reason for that.

7. Stay Calm And Carry On

Once you’ve come this far and found a manufacturer that you trust, it is time for them to get on with it. During this time keep these things in mind:

- The process may take longer than you expected. This is not unusual. Unpredictable events may arise and must be dealt with when making a new product.

- If making tools for plastic injection or die casting, assume that there will be several tweaks or modifications made to the tool before it comes out just right. This is the nature of the beast for new, untried products and it happens for all development cycles.

- Stay in touch with the supplier. If they are reputable, they make their living by delivering what they’ve contracted for.

- If you’re in geographical proximity to the supplier, a personal visit is better than an email. Being able to see and touch the first articles will give you, the first time inventor, a much greater and more tactile appreciation for the sophisticated nature of modern engineering and manufacturing and will alleviate concerns.

- If that is not possible, one of the advantages of modern communication is that with a Skype or other video call both parties can look at the part or tooling in real time and discuss any discrepancies.

Conclusion

The above may seem like a daunting list of proscriptions but don’t be deterred. We offer them up because, in our experience dealing with thousands of unique products, these insights represent the most likely way in which your idea may be delayed or derailed.

We don’t want that to happen, and of course every year millions of people around the world are able to bring a new product to market successfully. We want you to do the same and we’re here to help make the process as smooth and painless as possible. Contact us today to find out how we can put our experience to work for you.

Chris Williams is the Content Editor at Michigan CNC Machining Parts, Inc.. He is passionate about writing and about developments in science, manufacturing and related technologies. He is also a certified English grammar snob.