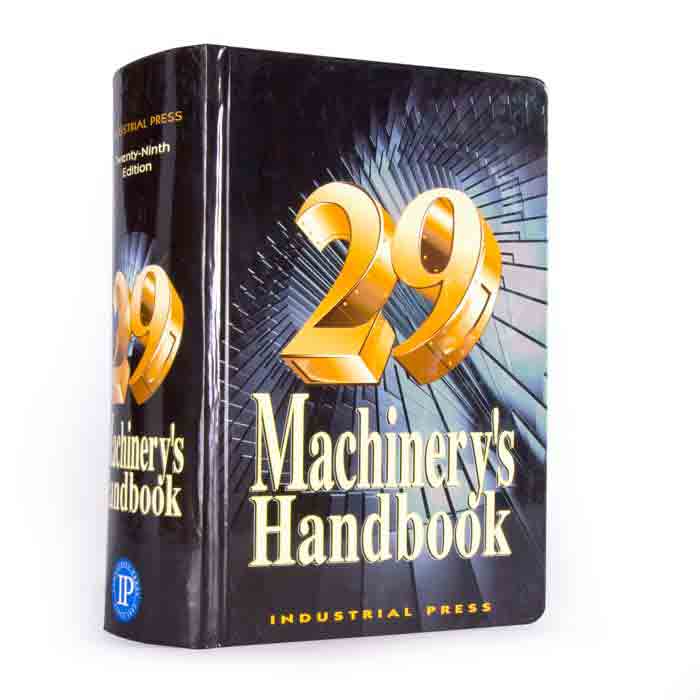

Image Credit:Industrial Press

Although it’s now digitized on CD-ROM, Machinery’s Handbook still remains The Book to turn to for a vast amount of information relevant not only to machinists but also product designers, tool makers, engineers, inventors and hobbyists who want definitive information about how things are made with machine tools. Let’s take a closer look at its history and why it’s so important.

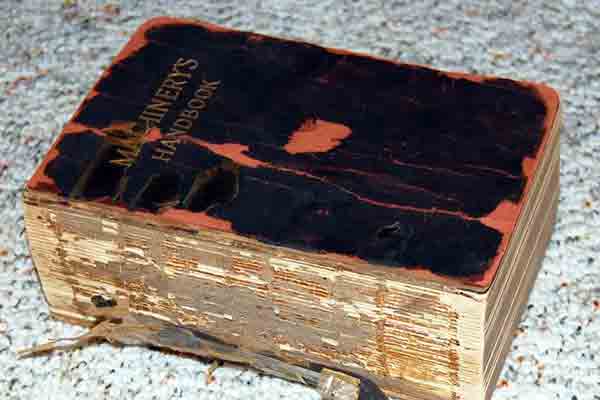

Now in its 29th edition, Machinery’s Handbook was first published in 1914 and has been continuously updated to reflect advances in machine tool technology, materials and best practices. It’s a remarkably collaborative work, a compilation of hard-won knowledge culled from the practical experience of thousands of unsung heroes in the metalworking trades who learned by doing and who captured that information for all future generations to benefit from.

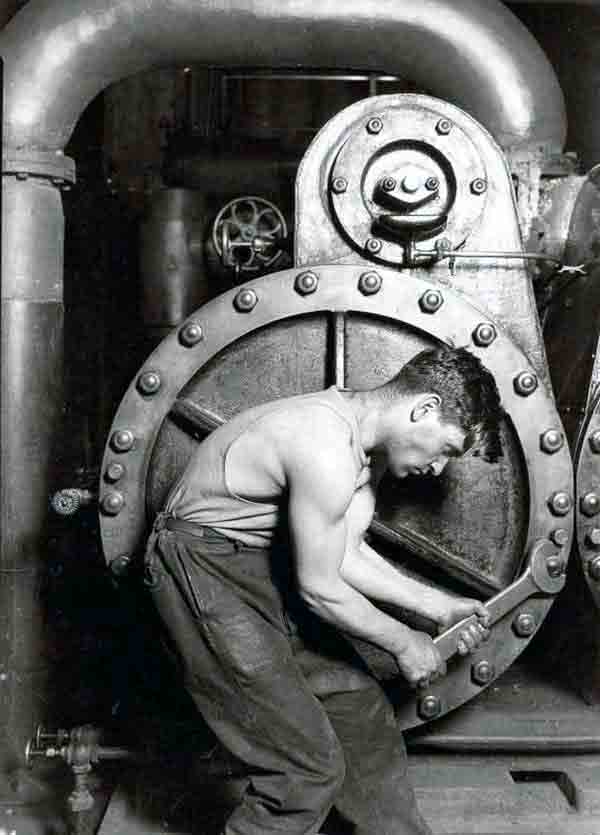

The end of the American Civil War in 1865 necessitated a massive rebuilding of the nation’s infrastructure, which also coincided with a vast influx of European immigrants who created the labor pool to fuel the Industrial Revolution. One of these was Scottish immigrant Alexander Luchars who arrived in New York City, entered the metal working trades, and eventually started the monthly magazine Machinery to cater to workers in need of the latest information about machines, techniques and materials.

Luchars was assisted by two able editors, Erik Oberg and Franklin Jones, who not only had solid foundations in math, physics and mechanics but who could also explain theory and practice in clear, practical language.

This emphasis on pragmatic and accessible information coupled with theory was immensely successful and is still the hallmark of the reference work today. The original Machinery’s Handbook took five years to produce, ran to more than 1800 pages and was printed in a dense, leather-bound volume exactly 7″ x 4.625″. More than 30,000 copies were sold in two years.

So important did this book become in a number of related trades that there was even a special drawer built into the machinist’s toolbox that was designed to hold it for quick access.

And when you open it up, what do you find? Information about speeds and feeds for all kinds of cutting heads and drills; heat treatment, forging and cutting of metal; gears and threads; fasteners; mathematic tables; measurements and dimensions and a great deal more. New editions of course are getting thicker, making room for CNC machining, laser 3D printing, waterjet cutting, robotics and other technologies that didn’t exist in 1914.

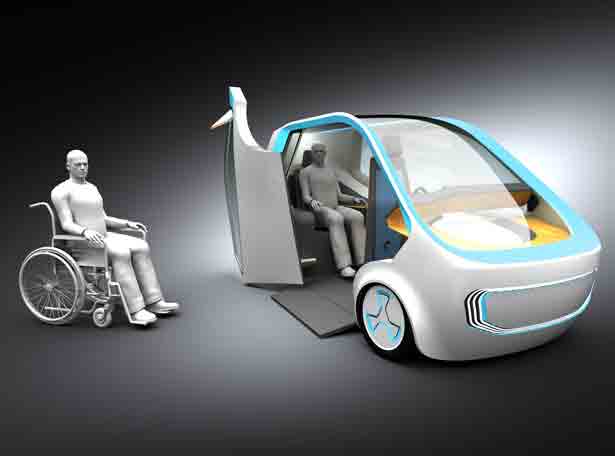

It’s not a “how-to” book, any more than a dictionary can teach you how to speak a language. It contains plenty of useful data, but the worker needs to know how to turn the handles. Works such as this form the necessary theoretical and practical foundation for the machinist’s craft, yet it takes experience to put that knowledge to work. We know a thing or two about how that is done. Contact us to learn more about what we can make for you.

Chris Williams is the Content Editor at Michigan CNC Machining Parts, Inc.. He is passionate about writing and about developments in science, manufacturing and related technologies. He is also a certified English grammar snob.