CAD software has, for more than 50 years, been a boon to industrial designers, product engineers and the manufacturers who turn design ideas into finished objects. During this time, production techniques have evolved to include metal 3D printing, digital object mapping and high-speed, multi-axis CNC machining centers while CAD programs have remained relatively unchanged.

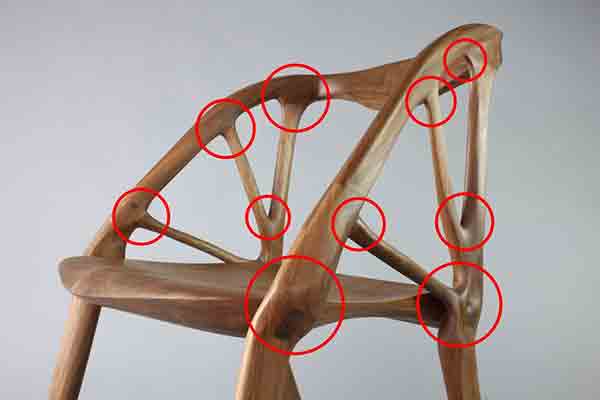

The Elbo chair was created by the AutodeskTM development lab using Dreamcatcher® software

Now generative design software is allowing engineers to use the computing power of the cloud to create design solutions that are better able to fully exploit the array of manufacturing processes at their disposal.

How Does Generative Design Work?

The use of CAD software to model an engineer’s idea is considered explicit design. It is the designer, architect or product inventor who decides what they want the product to look like, and then they explicitly tell the software how to draw it. This drawing is used as the basis for manufacturing.

The mosCELLS table mimics the natural development of plant structures

Alternately, generative design starts with the design intent– what the object is intended to do – and then creates many possible shapes to fulfill that objective. It’s able to do this by linking together the computing power of thousands or even millions of processors in the cloud, coordinated by the software’s unique algorithm.

What Is The Role of the Product Engineer?

The product engineer is responsible for inputing the various design parameters or constraints. When making a chair, the designer might say how tall they want the seat height, or how much weight it should bear – whatever is critical to that component.

nTopology has released a free version of their Element generative design software

Using that set of initial rules, the software is free to generate multiple possible solutions to fulfill the conditions. The engineer can then study the mechanical properties of these solutions while also deciding which one looks best or meets some other subjective requirement, which is something the computer can’t do.

Why Is This So Valuable?

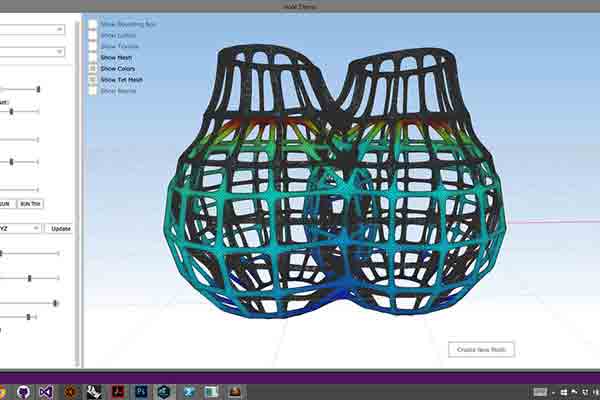

The value of this approach is that thousands of iterations can be done much more quickly than any designer could possibly draw them. Even more importantly, when working with advanced materials and sophisticated processes like 3D printing, generative design can crunch the huge computations necessary to calculate the mechanical stresses and thermal loads on complex shapes like lattice structures.

This motorcycle swingarm was designed by Dreamcatcher® to be as light as possible and still strong.

Notice that so many generative designs are reminiscent of the lattice structures of bones, tree branches and other organic forms. Mother nature has used this generative process for millions of years to perfect living creatures that are optimized for their environments, with no unnecessary weight or bulk.

What is the Future of Generative Design?

AutodeskTMforesees a time within the next ten years when such software is capable of creating even larger structures, such as entire buildings, but we are not there yet. Right now those calculations are still too complex.

One of the ideal applications of generative design is in medical appliances.

Perhaps the most intriguing prospect is on the smallest scale, where generative design can be used to optimize material at the microscopic level. This would be especially valuable for medical implants that must be light, strong and have complex organic structures to promote bone and cell growth.

These are fascinating developments that show the potential value of combining advanced computing power, intelligent engineering and human aesthetic judgement together to create amazing things. Have something amazing you want to create? Upload your CAD designs now for a free quote.

Chris Williams is the Content Editor at Michigan CNC Machining Parts, Inc.. He is passionate about writing and about developments in science, manufacturing and related technologies. He is also a certified English grammar snob.