Claris Healthcare and StarFish Medical

Case Study

Collaboration is the key to successful new product launches. An example of this is when advanced new medical devices come to life due to the vision of a team of doctors, therapists, engineers and manufacturing specialists working closely together.

Michigan CNC Machining Parts, Inc. recently partnered with StarFish Medical and Claris Healthcare of Canada to help them create injection molding tools and prototypes for an innovative wireless health monitor that supports physical therapy and rehabilitation after knee repair and replacement surgery. Here’s how we did it.

About The Partners

Claris Healthcare

Claris Healthcare created and maintains a platform of hardware and software applications that work seamlessly together to offer integrated solutions for rehabilitation, chronic care, telehealth and social care.

StarFish Medical

StarFish Medical is Canada’s largest provider of product design and development services for medical devices. They teamed up with Claris Healthcare to design the Claris Reflex, and when it was time to proceed with prototyping and fabrication they turned to Michigan CNC Machining Parts, Inc..

Claris Reflex

Combining accelerometers, bend and temperature sensors, the Claris Reflex is a wireless monitor and coaching aid for people recovering from knee replacement surgery. It constantly monitors movement and limb placement and uploads that information to an interactive app. By targeting specific strategies, caregivers and patients work together to reduce recovery times and improve health outcomes while reducing costs for providers.

About The Project

Michigan CNC Machining Parts, Inc. was tasked with making plastic injection mold tools for the main sensor housings. We also made separate injection mold tools to produce the thin and flexible plastic pads that help to affix the unit to the wearer.

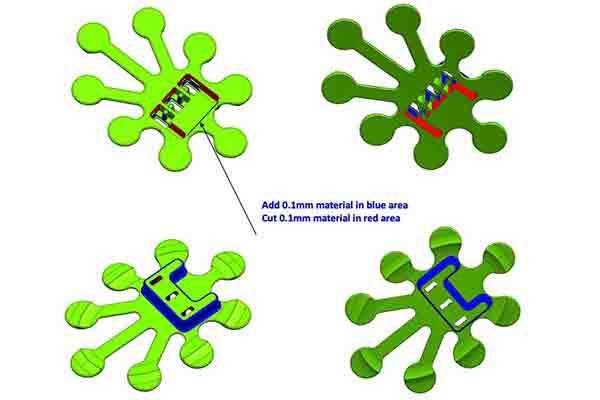

DFM Review

Star’s team of tooling engineers carefully reviewed the CAD files provided by StarFish, and indicated a few areas that we recommended for modification.

This design for manufacturing review is an essential part of the NPI journey. Michigan CNC Machining Parts, Inc. has experience in developing thousands of new products for many industries, which makes us qualified to lend our expertise when optimizing designs to suit the needs of production. This in turn helps to reduce product lead times while offering better quality at a lower cost.

The Result

The result of this collaboration is a Class I medical device that is easy and comfortable to wear, and that provides a continuous stream of useful information to positively impact human health.

Michigan CNC Machining Parts, Inc. is proud to have been a part of bringing this new product to market. It’s just one way we’re committed to being a reliable partner for medical device manufacturers who need fast turnarounds with the most professional service. You can learn more about our successful collaborations from these case studies. Our team is standing by to offer a competitive quotation when you upload your CAD files today.

Chris Williams is the Content Editor at Michigan CNC Machining Parts, Inc.. He is passionate about writing and about developments in science, manufacturing and related technologies. He is also a certified English grammar snob.