Metal 3D Printing Used To Craft Unique Jewelry Designs

Materials: Ti-64

Quantity: 45 Pcs.

Meet Veronica Nunes

“I am a Brazilian jewelry designer, goldsmith and founder of VNunes. I started my jewelry line in 2009, when I was living in NYC and had my own studio in Brooklyn. I take inspiration from nature and architecture to design my collections. As a jewelry designer, I am focused on designing attractive wearable objects that will enhance and fit the human body comfortably.”

Veronica Nunes modeling her custom jewelry creations.

Initial Concepts

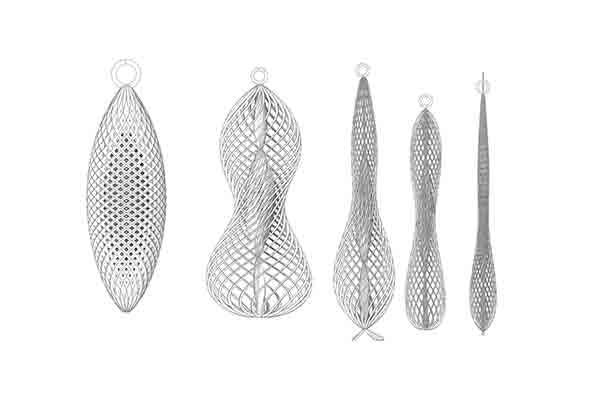

Veronica tested her ideas with many drawings such as these. After all, beautiful designs don’t spring to life automatically. They are the result of carefully refining profiles, proportions, light and heavy spaces until the perfect balance is achieved.

The 3D Printed Project

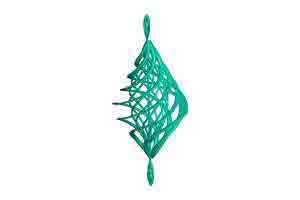

Veronica finally settled on her designs for a necklace, ring and earrings, and teamed up with Michigan CNC Machining Parts, Inc. on a joint project to bring these art pieces to life. However they still needed to be modified to conform to the unique requirements of 3D metal printing, which can be a challenging exercise in design engineering.

Designing for Additive Manufacturing

Although she is a trained designer with experience in CAD, Veronica had never worked before with the specific demands and limitations of the 3D metal printing process. Therefore, she collaborated closely with our engineer Chloe Kow to make slight modifications for optimal results. Here are some highlights.

We work closely with our clients to help them get the most out of their 3D printed designs.

Recommendations Following Design Review

Some of the recommended design modifications included:

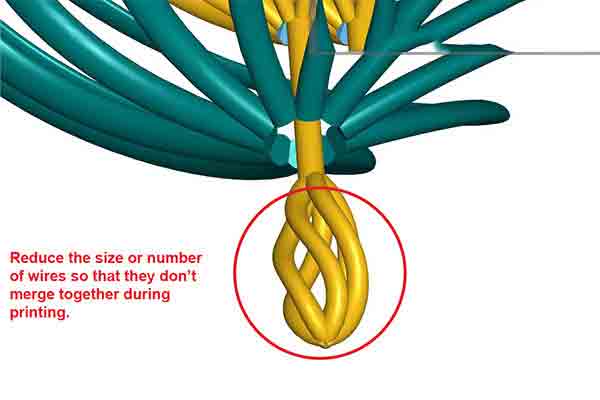

Wire Detail

Any gaps smaller than 500 microns will blend together.

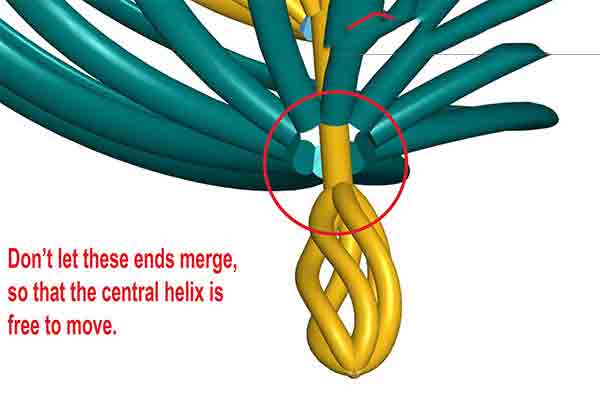

Moving Parts

Moving parts require extra clearance

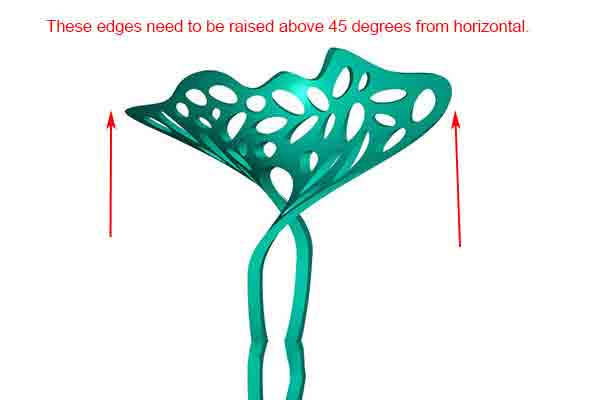

Overhang

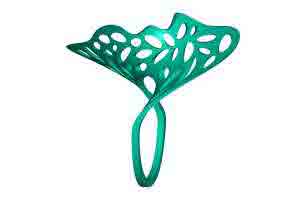

Gravity will cause unsupported areas to deform.

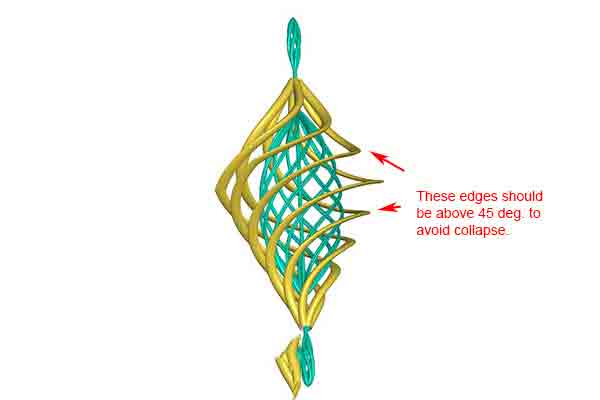

Blade Detail

Metal 3D printing requires careful design engineering

Preparing the Machine

Our Renishaw AM250 printer is a state-of-the-art direct metal laser melting (DMLM) machine. It uses a 200W ytterbium laser to fully melt metal powders into dense solids.

Titanium powder

Printing

Our engineer input the program into the control software which sliced the design into thousands of discrete 2D layers. Now it was time to start printing!

Laser beginning to melt the first layer.

Parts begin to emerge from the surrounding powder.

Excess loose powder is brushed away and can be recycled for the next project.

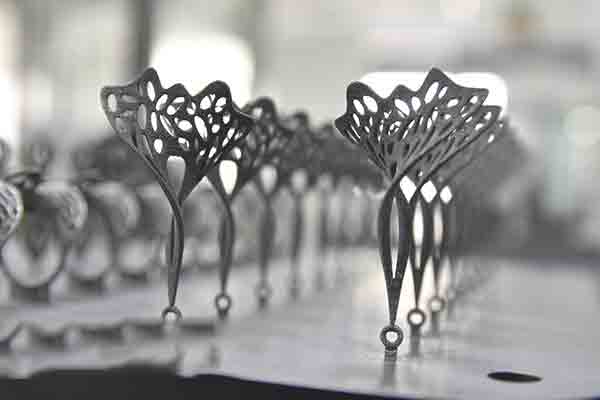

Different shapes can be programmed to share the same build platform.

Notice also the careful part orientation. Our engineer arranged the parts to make maximum use of the build volume while also limiting the number of supports and preserving the part’s geometry. This is important for conserving time, material and cost during the build.

Semi-finished parts have a rough look.

Careful deburring and polishing in our model shop.

Veronica’s full collection, plated and ready to wear

Want To Learn more about Metal 3D Printing?

A great project like this is the product of careful engineering, manufacturing expertise and close collaboration with the client every step of the way. If you’d like to know more about how to design for metal 3D printing, we offer free face-to-face training at our facilities in China as well as online metal 3d printing video tutorials.

And when you’re ready to make your masterpiece, we’re ready to offer a free quote and expert advice to get you started. Contact us today!