OTTO Digital Camera Prototype Made with Plastic Injection Molding

Services: CNC machining, Plastic Injection Molding, EDM, Assembly

Tooling Material: P20 Tool Steel

Tooling Lead Time: 14 days

Injection Material: ABS/PC

Production Lead Time: 5 days

Quantity: 530

About The Product

OTTO is a hackable, low-cost digital camera powered by the Raspberry Pi programmable controller. The OTTO comes with a ton of modes that define all the ways it can be used to take pictures, including creating GIFs or being tailored for shooting only beautiful sunsets. The OTTO pairs with your smartphone via the app, so you can immediately share your pictures to your phone and via your social network. User-customized modes allow for almost infinite possibilities, and it looks really nice, too.

About The Client

Next Thing Co. is a young tech start-up based in Oakland, California. They specialize in small open-source electronic devices with a distinctive hacker-inspired, stripped-down aesthetic.

Thomas Deckert of Next Thing visited Michigan CNC Machining Parts, Inc. in June of 2014 as part of the HAX accelerator program based in Shenzhen, China. Upon that visit Thomas saw the facilities and spoke with the staff and realized that Star would be the ideal partner for helping Next Thing to create their camera prototype.

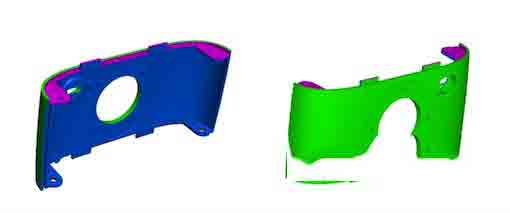

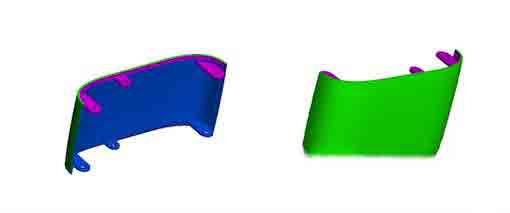

“We worked with Star to produce some of the components for our OTTO prototypes. We were so impressed with these pieces that when it came time to order injection mold tooling for our production run we knew we could count on Star to deliver. It was my first time designing and producing injection-molded parts (OTTO’s blue, front and rear housing) and I wasn’t sure how it would turn out. But Star’s team made a fantastic mold and, aside from some texture and polish, the parts came out perfectly the first time!”

About The Project

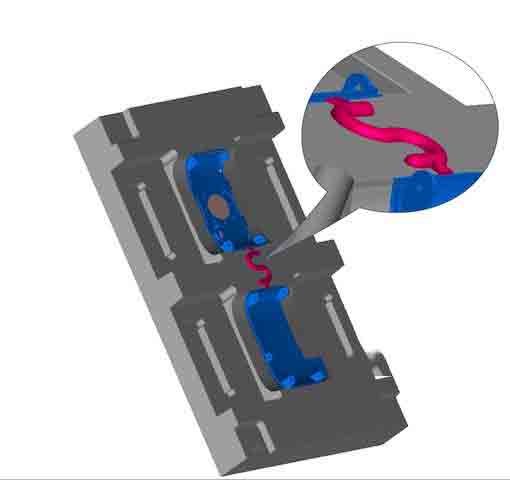

Michigan CNC Machining Parts, Inc. built a two-cavity mold from P20 tool steel. P20 is a semi-hardened steel that we first machined with EDM, then finished with CNC machining. EDM allowed us to create a textured pattern on the cavity of the mold, which produces the distinctive grain of the camera body.

It required only a few days to plastic injection mold a relatively small order. But the quality of the tool steel is sufficient to reliably make many thousand more pieces depending on the success of the initial prototype.

The OTTO front cover

The OTTO back cover