Vingtor Stentofon Intercom Substation Case Study

Services

Fabrication: CNC Machining

Finishing: Anodising, Aqua Blasting, Laser Etching, Polishing, Painting, Silk Screening

Materials: Aluminum, PMMA, PC

Lead Time: 10 days

About The Client

Zenitel is a company based in Norway who specialize in communication devices and network services for security and emergency management at schools, industry and maritime. They contacted our team at Michigan CNC Machining Parts, Inc. for help in making prototypes of two new IP intercom and public address sound systems for their Turbine series.

About The Prototype

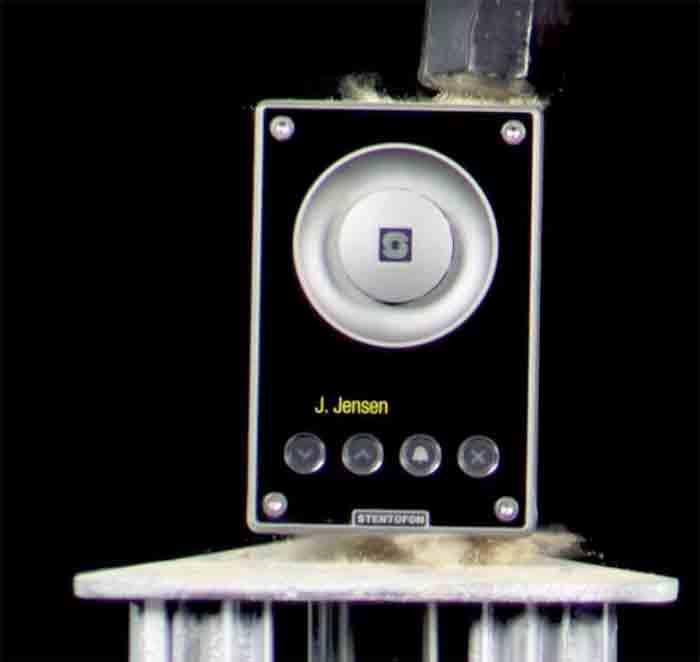

These two units were designed to be proof-of-concept prototypes for Zenitel’s new line of public broadcast and emergency intercom loudspeakers, the Turbine Series. Turbine speakers come in 37 intercom variants offering communication solutions for all environments including building security, industry and infrastructure.

Although intended for final acoustical and mechanical verification, the customer found the fit and finish so good that they were used for initial product promotional photographs.

How The Parts Were Made

The main housing was CNC machined from a solid blank of aluminum on a multi-axis mill. CNC milling is ideal for small volumes of prototypes. Had this been a larger production order, we would recommend pressure die casting as the best method for making multiple high-quality copies quickly and inexpensively per part.

Aqua blasting was then used to clean the surface and remove minor imperfections, while also imparting a subtle surface texture that is more refined than sandblasting. Once the surface was prepared it was then anodized, which provides a protective coating against salt spray or other corrosive environments.

Both prototypes used laser etching to mark the surface of the PMMA front cover. The black Stentofon prototype was polished, painted and silk-screened with a translucency of 50%. The yellow Vingtor prototype was silk-screened with yellow and then additionally silk-screened to 50% translucency on those areas with the illuminated indicator lights beneath the cover.

Finished Results

We take great pride in getting the little details just right. A project like this requires that all of the components fit together into a finished assembly that looks as refined and polished as a full production piece but done in a fraction of the time. This attention to detail is most critical in tight corners, on the faces of mating surfaces and in uniformly crisp, clean edges. Our paint shop also did a great job in matching the customer’s color requirements for the front enclosure panels.

What impressed us the most was the immaculate finishing. The front of the aluminum frame was 100% mark free, radiuses were sanded/sandblasted to correct dimension and the entire front surface was blasted to simulate the soft look one would expect from a cast part. All while keeping edges clean and sharp. The PMMA front plates were very neatly cut and tolerances were tight. Color was accurate, exactly as specified.

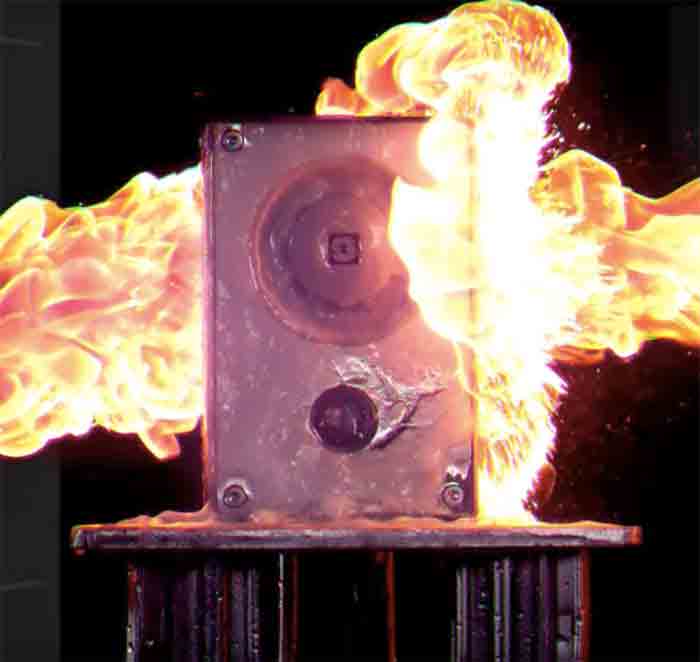

You’ll probably never need to subject your intercom system to abuse, but for emergency purposes it’s good to know that these units are dust proof, fireproof, waterproof, impact resistant and can keep on working even in sub-freezing temperatures. Find out more about the Turbine series at www.zenitel.com or watch them being put to the test on their YouTube video.

When you’re ready for your next rapid prototypes or low-volume production to be this good right out of the box, contact our multilingual staff today for a quotation or send us your files for a project review.

Having not worked with Star before, I was extremely impressed by the level of service and the quality of prototype produced. They certainly live up to their promise of delivering Western quality, so much so that we’ve already placed additional work with them.

This job is a great advertisement for what we do so well, highlighting as it does our ability to turn jobs around exceptionally quickly, and the fact we do so with the greatest attention to detail and our eyes firmly focused on the quality of the prototypes produced.