Finishing Services

What Makes a Great Paint Job

When people think of paint, they tend to think of it in a general sense. They often picture a smooth liquid substance that—once applied to a surface—can bring walls, buildings, and furniture to life. The definition doesn’t do justice to the...

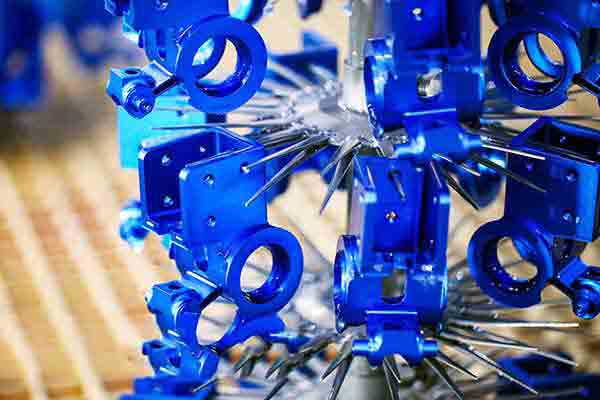

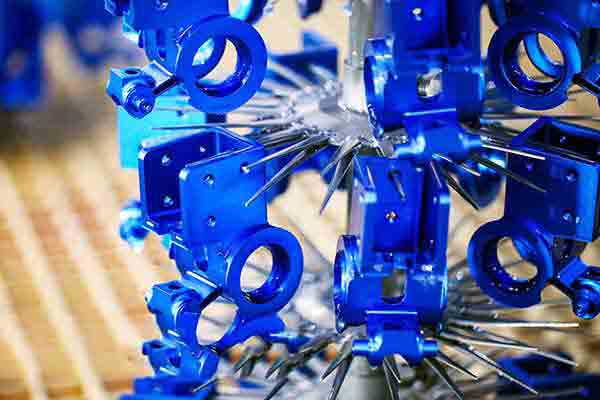

8 Things You Need to Know About Anodizing Aluminum

Anodizing is a method for changing the surface chemistry of metals and other substrates. It protects against corrosion, enhances aesthetic qualities, resists scratching and is one of the most durable surface finishes available. Let’s take aluminum as an example to see how this process cleverly exploits oxidation for a result that’s both decorative and functional.

What are the Top Passivation Techniques?

What Does Passivation Mean? Passivation means to alter the chemical structure of a metal at or just below the surface, so that it’s more stable and doesn’t want to react with other elements in an undesirable way. There are several different...