There’s a plethora of reasons for why new products fail. Some are related to the market itself whilst others are related to issues with the product’s design and functionality.

Thinking of a product idea and turning it into a 3D model might seem like a sufficient way to find out if the product will work. But unfortunately many products go to manufacturing with design flaws that could’ve been rectified earlier in the process. So how can you make sure that your product doesn’t suffer this terrible fate?

Use an Iterative Design Approach for Product Development

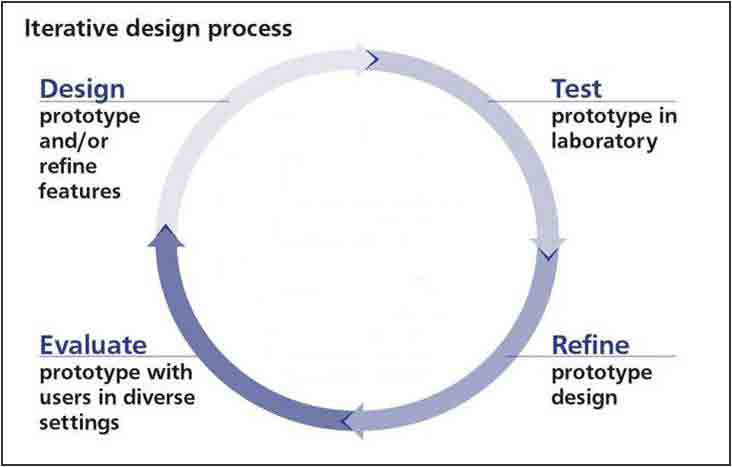

Iterative design is a method where you’re constantly revisiting the original premise of your idea or product, finding out what works and what doesn’t and then modifying. With an iterative design approach you can prototype, test, analyze and then refine the product until you feel it’s ready to hit the market. By using this method you can improve both the functionality and quality of your design. If you’re producing something that has to be assembled, or a multi-part product, the prototyping stage is an excellent time to test whether the parts line up correctly.

The iterative product design process

This type of product development is not just ideal for testing functionality. If your product uses aesthetics as a heavy selling point there’s no better way to test its reception by customers. With a high-quality prototype you can test how customers feel about the surface finish, color, size and grip.

Use Cost-Efficient Prototyping Methods

Rapid prototyping is an excellent way to not only get your hands on a physical part or product, it’s also a great way to revisit your original business idea and see whether your intended promise holds up. The world of product development can be quite tough and you’re most likely dealing with a limited amount of funds. So by using cheap and reliable prototyping methods you can save yourself both time and money further down the line.

In order to do product design iteration through prototyping we suggest you use a method that is cost effective and can deliver your product in hand as quickly as possible. Our two most popular rapid prototyping methods, and the one’s that instantly spring to mind include CNC machining and vacuum casting.

CNC Machining

CNC machining is a popular method for prototyping products using a large variety of materials. With CNC milling and turning you can quickly create highly accurate parts and products. Another benefit of this process is that once you iterate your product design after the initial prototype, you can easily adapt the CNC program used for the initial prototype in order to quickly create your second iteration.

CNC Milling Plastic

Vacuum Casting

Vacuum casting is a prototyping method that allows you to quickly create up to 50 high-quality prototypes for initial testing. A master mold is used to guarantee that each batch is identical, increasing reliability when sending them out for initial product testing. One of the main benefits of vacuum casting for this type of prototyping is its low cost. It lends itself to testing multiple variations of a product design for rapid product development.

When selecting your prototyping method it’s important to take into account the cost as well as the production time for each method. A reliable manufacturer can give you an accurate estimate of the production time with an initial product quote.

Sealing a Vacuum Casting Mold

At Michigan CNC Machining Parts, Inc., we offer a range of rapid prototyping methods that are ideal if you’re working with an iterative product development method. We can also support you in low-volume production to allow you to test the market before producing larger quantities. So go ahead and get in touch and we will provide you with a free project quote and together we can work on making your next project a reality.

Chris Williams is the Content Editor at Michigan CNC Machining Parts, Inc.. He is passionate about writing and about developments in science, manufacturing and related technologies. He is also a certified English grammar snob.