One reason Michigan CNC Machining Parts, Inc. recently partnered with Guhring tools of Germany is because of their proven technology in applying thin film coatings to their cutting tools. Let’s look at why these thin films are so important to tool performance and how this translates into improved quality for the CNC machined parts we make for you.

What Problems are Created if a Tool Fails?

A manufacturing environment can be incredibly harsh on cutting tools. They must slice through hardened and tempered metal alloys at high speed, hour upon hour, without complaint and with a high degree of accuracy. When something goes wrong, that usually means the cutter is dull, chipped or broken altogether.

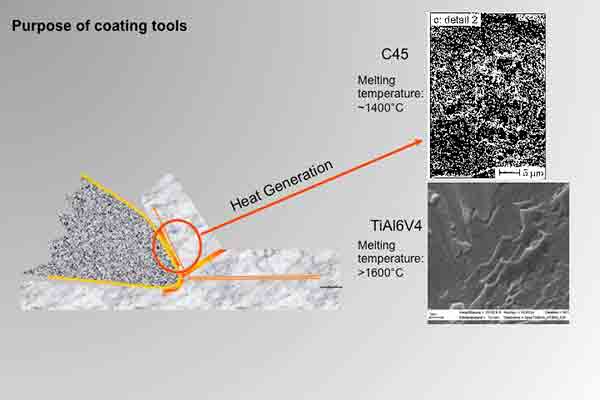

Excessive heat and friction can make a cutter fail, potentially breaking inside a part and destroying the workpiece.

If a cutter fails it must of course be replaced. Some can be reground but this adds time and expense. Cutters that are excessively worn will lose their dimensional accuracy and leave a poor surface finish. Mills and drills can also be quite expensive investments so it pays to ensure they last as long as possible for maximum efficiency and cost-savings.

What is a Thin Film?

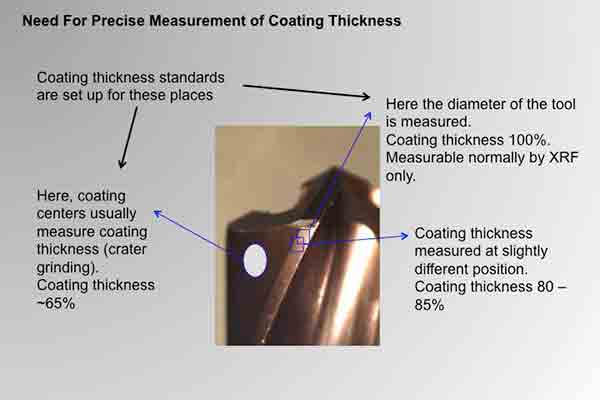

A thin film is one or more layers of a material that’s been coated to another surface using a special kind of evaporation. These coatings are very thin, down to the molecular level. Usually layers are built up to micrometer thickness for durability and sometimes different films are overlaid for greater performance.

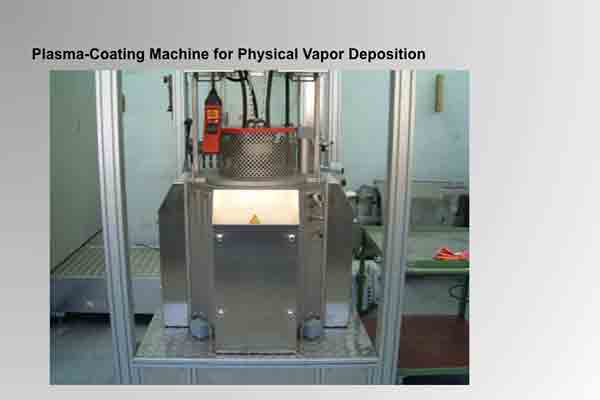

How are Thin Films Applied?

Most thin films are applied using a process known as Physical Vapor Deposition (PVD). The coating material, or “target”, is placed in a vacuum chamber and then bombarded with a laser, an electron beam or some other energy source. This causes the target to evaporate into a highly charged plasma vapor. This vapor is electrostatically attracted to the substrate – in this case the cutting tool – and bonds with it at the molecular level, condensing back into a solid with a very strong surface adhesion.

What is the Purpose of a Thin Film?

The purpose of a thin film is to alter the chemical and physical properties of the tool right at the edge where it contacts the workpiece. This helps to achieve many desirable effects, including reducing friction, increasing toughness and hardness, resisting heat or to enhance compatibility with particular materials.

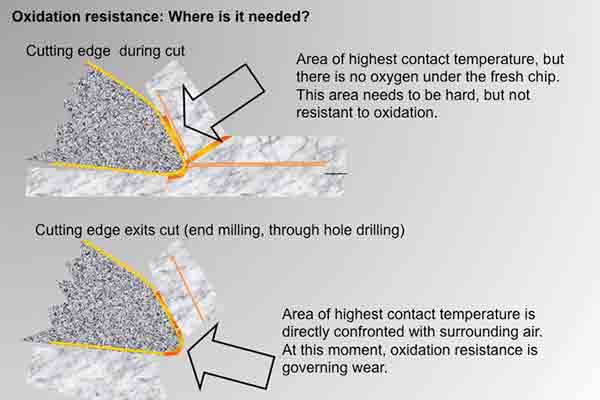

Thin films also reduce the chance of oxidation when the hot tool tip is exposed to the atmosphere, which can rapidly degrade a tool’s edge.

How do Thin Films Improve Manufacturing?

Most CNC cutting tools are made from type C2 or C7 tungsten carbide. This is a sintered metal made from a combination of tungsten, carbide, titanium and cobalt. This metal is extremely hard and durable and can take a lot of abuse, but its attributes can be improved with the right thin film coating.

Lubrication

Some additives are used to reduce scuffing, cold welding and seizing. This is useful in operating conditions where there is little or no lubrication, such as in clean room environments. It improves the cutting of some types of aluminum, which is a soft metal that tends to melt easily at the cutting edge and stick to the face of the tool.

Heat Resistance

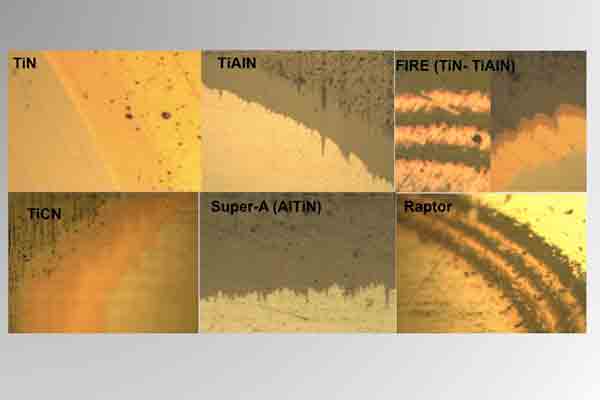

High-speed milling operations generate a lot of heat even with lubrication, and this heat can cause the sharp edge of the tool to go dull quickly or to chip. AITiN coatings increase the oxidation temperature, or the temperature at which the coating begins to chemically degrade. Titanium nitride coatings also improve surface hardness.

Toughness

The ability of a material to resist tearing is a measure of toughness. Stainless steels and vanadium steels are alloys that are notoriously difficult to machine without destroying cutting tools, so special compounds of titanium are used to increase surface toughness and prolong cutter life. This kind of coating is not especially durable under high heat stress, so it’s best used for low-speed applications like threading and broaching.

Hardness

Another metallurgical term, hardness refers to the ability of a material to resist scratching and abrasion. Here, titanium can be mixed with carbon (TiCN) to increase hardness for the toughest applications in exotic alloys such as would be used in aerospace.

Titanium is also a difficult material to machine and can chemically bond with the titanium coating of some cutting tools, so a layer of zirconium nitride (ZrN) can be used because it’s chemically inert to titanium.

Setting up for a CNC milling project.

How Does This Help You?

The above examples show just some of the ways that we work hard to control all aspects of our performance when doing rapid prototyping and low-volume manufacturing. Matching the right cutting tool to the workpiece increases speed, improves finish quality, maintains accuracy and lowers costs for you. This is the kind of professional service you can expect when you contact us for a free quote on your next project.