CNC

Everything You Need to Know About CNC Turning Centers

Modern CNC machine turning centers have come a long way from their forebear, the humble lathe. With the advent of computer controls and multiple directions of travel, these amazing workhorses can do turning and milling operations on one fast and accurate machine.They...

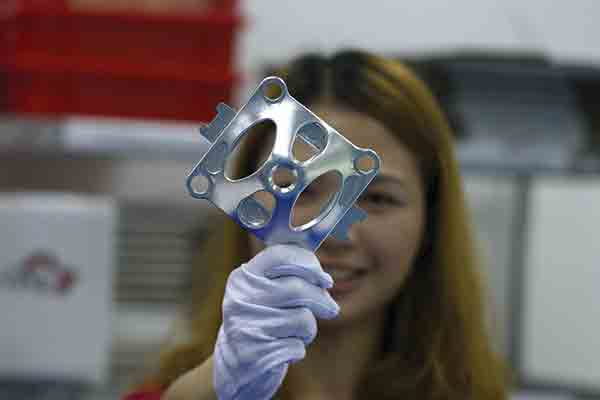

Improving CNC Machined Parts with Thin Film Coatings

One reason Michigan CNC Machining Parts, Inc. recently partnered with Guhring tools of Germany is because of their proven technology in applying thin film coatings to their cutting tools. Let’s look at why these thin films are so important to tool performance and how this translates...

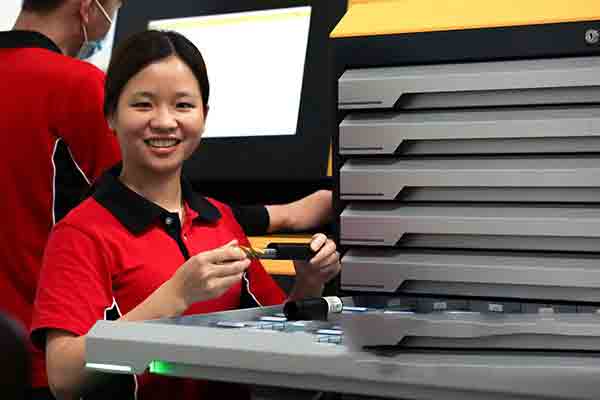

How is G-Code Used to Make CNC Machined Parts?

What is G-Code? G-code is a generic term for a programming language used to instruct a numerically-controlled machine tool. It controls all aspects of machine movement including spindle speed, the tool path, how fast to move and where to locate itself in a multi-axis...

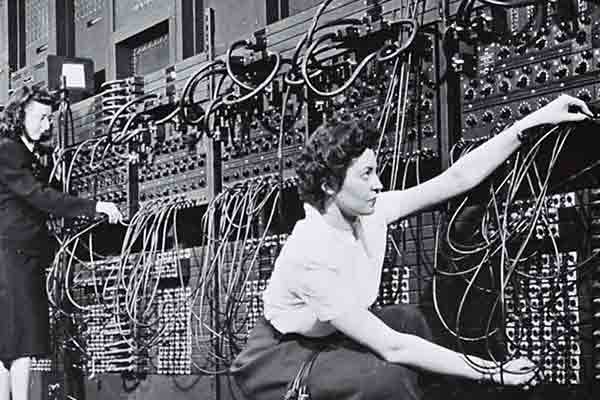

6 Early Inventions in the History of CNC Machining

All CNC machines, regardless of their size or complexity, make use of the same few technical innovations – some more than one-hundred years old. By tracing the history of these innovations we can follow the trends that led to the development of the first...